Polythene(PE) coatinghas long been the backbone of the paper cup industry. Its ability to hold a wide range of beverages, from hot coffee to cold water, without compromising structural integrity has made it the preferred choice for many manufacturers.

The advantages of PE coating include:

- Tough and elastic, enhancing the durability of paper cups

- Provides essential thermal protection in extreme temperatures

- Keeps drinks warm, ensuring hot drinks stay hot and cold drinks stay refreshing.

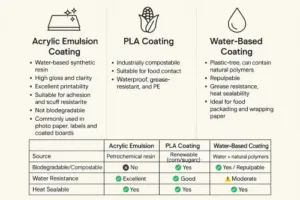

However, PE coatings have their drawbacks, especially when it comes to environmental sustainability.

While PE coatings are excellent at preventing leaks and spills, their impact on the environment cannot be ignored. As we delve deeper, we’ll explore the benefits and limitations of polyethylene-Coated paper cups.

What is PE Coating:

PE coating or polyethylene coating is the process of applying a thin layer of polyethylene to paper cups to protect them from moisture or other environmental factors.

This process is known as extrusion coating and can be coated with different amounts of polyethylene to meet different requirements such as waterproofing or heat sealing capabilities.

This produces paper cups that are more tear-resistant, harder, durable and less prone to wrinkling.

PE coating is widely used because the application process is relatively simple and cost-effective.

PE coatings ensure that paper cups can withstand the rigors of everyday use, whether for hot drinks such as coffee or cold drinks.

However, as we shall see, the environmental impact of this coating is a major drawback that cannot be ignored.

The benefits of PE Coated Paper Cups:

One of the key benefits of polyethylene coated paper cups is their excellent resistance to liquids, water and grease.

This near 100% water resistance makes it an excellent choice for a wide range of beverages, ensuring that the cups will not leak or spoil.

The polyethylene coating greatly enhances the board’s key properties of moisture and grease resistance. In addition, it improves the overall durability of the board.

This durability is critical in food packaging as it ensures that the integrity of the cup is not compromised when serving hot or cold beverages.

Whether it’s a hot cup for your morning coffee or a cold cup for a chilled beverage, PE coated paper cups offer consistent performance, making them a versatile choice for the food packaging industry.

The shortcomings and environmental issues:

Although polyethylene coated paper cups have functional advantages, it also brings serious environmental problems. Polyethylene is a non-biodegradable material that poses long-term environmental risks.

The recycling process of polyethylene coated paper cups is complex, requiring the separation of the polyethylene layer from the paper fiber, which often leads to inefficiency and increased waste.

In addition, the cost factors associated with polyethylene coatings need to be weighed against their environmental impact.

While polyethylene coatings offer a durable, reliable solution for beverage containers, recycling challenges and the non-biodegradability of polyethylene coatings require that their use be reevaluated in favor of more sustainable alternatives.

In summary, PE coated paper has certain advantages in food packaging, but there are also environmental protection and sustainability challenges, which need to be considered comprehensively when used.