More and more label printers are encountering inquiries from their brand owner customers about the choice between Coated One Side (C1S) and Coated Two Sides (C2S)paper for labels. While C1S paper has traditionally been the standard for producing paper labels, there is growing interest in exploring C2s paper as an alternative for commercial printing. This shift may be driven by factors such as availability, cost considerations, or simply a desire to challenge conventional practices. Understanding the differences between C1S and C2S papers is crucial, as these differences can significantly affect the manufacturing process and performance of the labels in their final applications.

Understanding C1S and C2S Paper

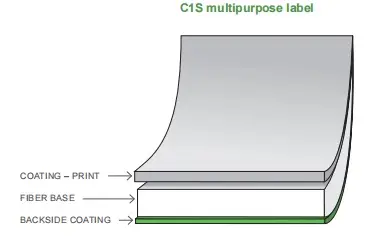

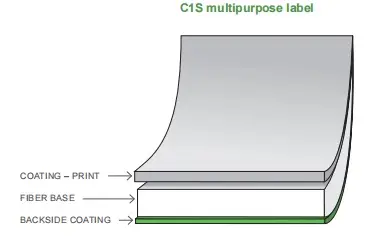

Before diving into the nuances of label printing, it’s essential to understand the basic structure of C1S and C2S papers.

-

C1S Paper: This paper type is coated with a smooth finish on only one side, typically with a clay or other fine coating material. The reverse side remains uncoated, making it more porous and suitable for writing, printing, or adhering to surfaces that don’t need a glossy finish.

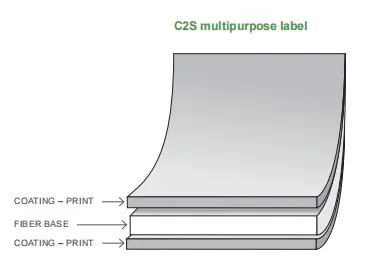

- C2S Paper: C2S paper, on the other hand, is coated on both sides. This dual coating gives it a smooth, consistent finish on both sides, ideal for applications that demand a uniform appearance and print quality across the entire sheet.

Why Choose C1S Paper for Labeling?

For years, C1S paper has been the default choice for labels due to its affordability, availability, and adequate performance for most standard labeling applications. Here’s why C1S is a popular choice for label printing:

-

Cost-Effective: C1S paper is generally less expensive than C2S, making it an attractive option for businesses looking to reduce costs without compromising print quality on the coated side.

-

Adhesion: The uncoated side of C1S paper is often more suitable for adhesive bonding, which is important for labels that need to stick to various surfaces like bottles, boxes, or containers.

-

Good for Single-Sided Printing: C1S paper is ideal for labels that only require high-quality printing on one side, such as product labels, barcodes, or branding elements. The uncoated back can also be used for additional information, instructions, or pricing.

-

Common Uses: C1S paper is widely used for food labels, product packaging, and promotional materials where one side needs to be printed with vibrant images or branding.

Why Consider C2S Paper for Labeling?

Although C1S paper is a staple in the industry, there are situations where C2S paper may be a better fit for label printing. Here’s why some brand owners are opting for C2S paper:

-

Superior Print Quality: With coating on both sides, C2S paper delivers a uniform print surface, ideal for high-end labels that require sharp, vibrant images and crisp text on both sides. This is particularly useful for applications like premium product labels or double-sided product information labels.

-

Enhanced Durability: C2S paper tends to be more durable, thanks to the additional coating. This makes it a better option for labels that need to withstand environmental factors such as moisture, abrasion, or heavy handling, like beverage labels or outdoor product packaging.

-

Professional Appearance: The glossy, smooth finish on both sides of C2S paper gives it a high-end look and feel, making it ideal for premium branding, luxury packaging, or high-value product labels.

-

Common Uses: C2S paper is often used for brochures, catalogs, high-end packaging, or labels that need a polished, consistent appearance throughout, such as those for cosmetics, electronics, or luxury goods.

Key Differences Between C1S and C2S Paper for Labels

| Feature | C1S Paper | C2S Paper |

|---|---|---|

| Coating | Coated on one side | Coated on both sides |

| Finish | Glossy or matte on one side, uncoated on the other | Glossy or matte finish on both sides |

| Print Quality | High-quality printing on one side | High-quality printing on both sides |

| Durability | Less resistant to wear and tear, especially on uncoated side | More durable, resistant to moisture, abrasion, and wear |

| Cost | More affordable | More expensive due to double coating |

| Applications | Standard labels, product packaging, promotional materials | Premium labels, luxury packaging, double-sided printing applications |

When to Choose C1S Paper for Labels

C1S paper is the right choice for labels that require a high-quality printed surface on one side, with the flexibility of a writable or adhesive-friendly back. If your label application doesn’t demand a pristine finish on both sides and cost is a major consideration, C1S is a great option. It’s perfect for labels on food packaging, basic product labels, and promotional materials.

When to Choose C2S Paper for Labels

C2S paper should be considered for premium label applications where the quality of the finish is paramount. If the label needs to be printed on both sides or requires superior durability (for example, outdoor products, cosmetics, or high-end packaging), C2S paper is the ideal choice. The extra cost is often justified by the enhanced performance, durability, and visual appeal.

When choosing between C1S and C2S paper for label printing, it’s important to consider the specific needs of your application. While C1S paper is the more cost-effective option and works well for most labels with single-sided printing, C2S paper offers superior print quality, durability, and a professional finish, making it the best option for high-end or double-sided labels.

By understanding the differences between C1S and C2S papers, label printers can provide their brand owner customers with the best possible solution for their labeling needs, ensuring a balance of quality, performance, and cost-efficiency.