In the global packaging and industrial materials market, selecting the Right Paper product is critical for performance, cost-efficiency, and compliance. However, many buyers often confuse greaseproof paper with silicone coated paper—a mix-up that can lead to costly mistakes, from product failures to customs delays. At SURE PAPER , we understand these challenges firsthand.

This blog cuts through the confusion by providing a clear, side-by-side comparison of these two materials, covering essential properties like grease resistance, heat tolerance, environmental impact, and HS codes. Whether you’re sourcing packaging for food products, industrial liners, or high-temperature applications, this guide will empower you to:

Avoid supply chain errors caused by misclassified HS codes.

Optimize costs by matching material properties to your specific use case.

Enhance product performance with science-backed insights into durability and compliance.

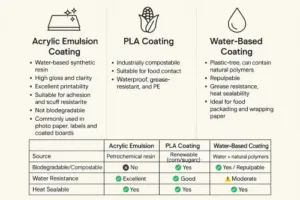

Product Characteristics Comparison Table

|

Characteristic |

Greaseproof Paper |

Silicone Coated Paper |

|

Grease Resistance Level |

Moderate to High (dense fiber structure resists oil, but may allow penetration with heavy/oily substances) |

Extremely High (silicone coating fully blocks oil and grease) |

|

Ignition Point |

~150–200°C (flammable due to cellulose base) |

~220–250°C (silicone layer resists heat, but paper base remains combustible) |

|

Grammage (g/m²) |

Lightweight: 20–50 g/m² |

Heavier: 38–80 g/m² (increased weight from coating) |

|

Water Solubility |

Insoluble in water, but softens when wet |

Insoluble in water; silicone coating repels water (surface waterproof) |

|

HS Code |

4806.2000 (ungreased greaseproof paper) |

4811.5900 (coated paper, silicone-based) |

Application Scenarios Comparison

|

Scenario |

Greaseproof Paper |

Silicone Coated Paper |

|

Food Packaging |

Burger wraps, pastry liners (short-term oil resistance) |

Baking parchment, chocolate molds (heat-resistant and non-stick) |

|

Industrial Use |

Anti-grease lining for machinery parts |

Label release liners, adhesive tape backing |

|

Eco-Friendliness |

Biodegradable (pure paper base) |

Silicone coating may hinder recycling (requires specialized processing) |

Key Notes

HS Codes: Ensure alignment with target country’s customs regulations (subheadings may vary).

Temperature Limits: Silicone paper is preferred for oven use, while greaseproof paper suits low-heat applications.

Environmental Impact: Greaseproof paper is more eco-friendly for single-use packaging.