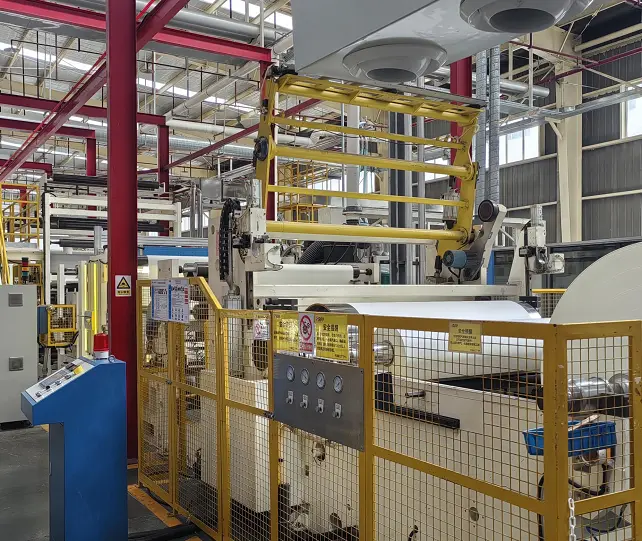

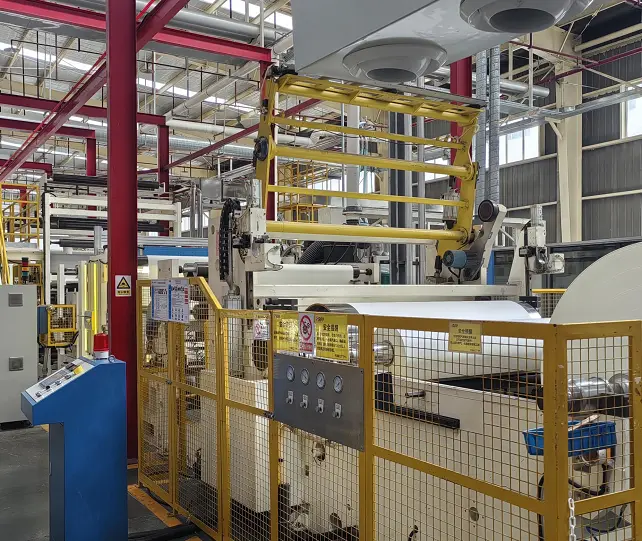

PE coated boardis a special paper product formed by attaching a plastic film (such as polyethylene PE) to the surface of paper through extrusion coating. It is widely used in food packaging, medical supplies, label printing, industrial protection, and other fields, featuring water resistance, oil resistance, good sealing properties, and excellent printability. In the production process of PE Coated board, “corona treatment” is a frequently overlooked but extremely crucial step. This article will delve into the principle, function, and significance of this process in the manufacturing of PE coated board, helping readers fully understand its technical value.

What is Corona Treatment?

(1) Basic Definition

Corona treatment refers to a “pre-treatment process” carried out on the surface of the original paper before plastic film coating (i.e., laminating). This process utilizes the corona effect generated by high-voltage discharge to produce high-energy electrons and active particles in the air, roughening the surface of the original paper, changing its surface tension, and cleaning, activating, and modifying the paper surface, thereby increasing its surface energy and wettability.

(2) Difference from Conventional Corona Treatment

In the production of PE coated board, “corona treatment” is generally divided into two stages: corona treatment of base paper and corona treatment of PE surface. The former is the treatment of paper before laminating, while the latter is the treatment of the plastic film surface after laminating. Although the principles are similar, the process goals are different: the former mainly enhances the adhesion between paper and plastic film; the latter focuses more on the adhesion for subsequent printing or bonding of PE coated board.

The Role and Significance of Corona Treatment of Base Paper

(1) Enhancing the Adhesion between Paper and Plastic Film

Original paper is typically made of natural cellulose materials, with a relatively rough surface and containing certain amounts of impurities and oil substances. When directly in contact with molten plastic, it is prone to “interface separation”. Through corona treatment, surface contaminants can be effectively removed, polar groups can be introduced, making the paper surface more hydrophilic and reactive, thereby enhancing the adhesion with the plastic film.

(2) Improving the Uniformity and Adhesion of Lamination

After corona treatment, the surface tension of the base paper increases, making it easier for molten plastic to spread and penetrate during coating, reducing defects such as bubbles and pinholes, and improving the uniformity and adhesion quality of the film layer.

(3) Reducing the Risk of Product Delamination

In humid or high-temperature environments, untreated paper and plastic film are prone to delamination due to inconsistent thermal expansion and contraction. After corona treatment of base paper, the paper-plastic interface becomes more firmly bonded, significantly reducing the risk of delamination during product use.

The Technical Principle of Corona Treatment

(1) Physical Mechanism

The corona treatment device generally consists of a high-voltage power supply, an electrode system (including metal rollers and electrode wires), and a cooling system. Its working principle is as follows:

- High-voltage discharge: The high-voltage power supply applies high-frequency high voltage (typically 8 to 20 kV) between the electrodes and the grounded metal roller, generating corona discharge in the air gap.

- Particle bombardment: During the discharge process, high-energy electrons, ions, free radicals, and ozone are produced, which bombard the surface of the base paper at high speed.

- Surface activation: Surface activation includes surface oxidation, surface etching, and free radical generation. Among them, surface oxidation involves the excitation of oxygen molecules to form active oxygen atoms, which react with the paper surface, introducing polar groups such as -OH and -COOH. Surface etching is achieved by using tiny physical impacts to create microscopic roughness on the surface, thereby increasing the surface area; the final free radical generation refers to the fact that after the original paper is subjected to corona treatment, the cellulose molecular chains on the surface of the original paper break, generating a large number of free radicals, which promotes the subsequent chemical bonding of the plastic film.

(2) Changes in Surface Tension

After the original paper undergoes corona treatment, its surface tension can increase from approximately 30 to 35 dynes per centimeter to over 40 to 45 dynes per centimeter. This change can be measured and verified using a dyne pen or the drop method.

Advantages and Limitations of Corona Treatment of Original Paper

(1) Main Advantages

Compared with traditional surface treatment processes, corona treatment is more environmentally friendly and energy-efficient. It does not require the addition of chemical reagents during the process and there is no solvent emission. Its operation is also simpler, with a high degree of equipment automation, making it easier to integrate into continuous production lines. The cost-efficiency ratio is higher compared to traditional processes, with a shorter investment payback period and a significant improvement in product yield. Finally, corona treatment can enhance the quality of PE coated board because it can strengthen the bond between paper and plastic, improve the printability and sealing performance of PE coated board.

(2) Existing Challenges

Of course, compared with traditional surface treatment processes, corona treatment also has certain limitations. Firstly, there is a higher requirement for timeliness: the treated original paper should complete the lamination process within a short period of time, otherwise the surface activity of the original paper will gradually decline over time. Of course, there are also differences in the types of original paper that can be treated: original papers with different fiber structures respond differently to corona treatment, so it is necessary to adjust the parameters according to the raw materials. Finally, there is a risk of over-treatment with corona: excessive treatment intensity may cause the paper to become brittle, yellow, or develop an odor.

Conclusion

Corona treatment of original paper, as a key pre-treatment step in the production of PE coated board, is not conspicuous but crucial. It not only directly affects the strength of the bond between paper and plastic but also indirectly determines the performance of the final product. Whether from the perspective of improving product quality or optimizing the production process, a deep understanding and scientific application of corona treatment technology for original paper are important steps in promoting the high-quality development of the PE coated board industry.