In the selection of packaging materials, both Coated White Top Kraft Paper and Glazed White Top Kraft Paper are widely favored options. Although they are structurally similar — both consisting of four layers: the top layer, underlayer, core layer, and bottom layer — the difference in surface treatment processes leads to significant variations in their characteristics, applications, pricing, and usage.

|

|

Coated White Kraft Board |

Glazed White Top Kraft Board |

|

specious |

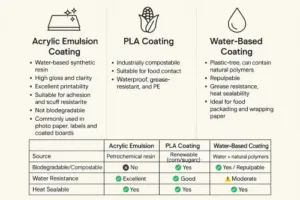

By applying one or more layers of coatings such as kaolin, calcium carbonate, etc. on the surface of paper, the smoothness, glossiness, and printing performance of the paper can be improved. The white surface of coated kraft paper is somewhat similar to the white surface of copperplate paper, and is relatively smooth。 |

Make the surface of the paper smoother and smoother by hot pressing or cold pressing, without any additional coating treatment. Therefore, the white surface of the white hanging kraft paper is relatively rough. |

|

features |

Has better printing effect, higher glossiness and smoothness. Due to its special surface treatment, it has good ink absorption and color reproducibility. |

Although the surface is relatively smooth, it is slightly inferior in glossiness and smoothness. Its characteristics are that the natural fiber texture is more obvious, the hand feel is rougher, and the printing effect is dull. |

|

usage |

In addition to making cardboard boxes, they are also commonly used for producing high-quality color printing, such as high-end packaging boxes, brochure covers, promotional materials, and other products that require exquisite printing effects. Domestically popular brands include: Mengniu, Yili, Uni President, Wahaha, Kangshifu, Haier, Lenovo, LG |

Suitable for general printing needs, such as ordinary packaging boxes, labels, envelopes, etc., where printing quality requirements are not particularly high. |

|

cost |

The price is usually higher than that of white flour kraft paper. |

The production process is relatively simple, the cost is low, and the price is relatively cheap. |

|

quantity used |

Due to its high-end characteristics and high price, it is usually used in products with high requirements for packaging quality and appearance, with relatively less usage. |

Due to its high cost-effectiveness, it is widely used in various daily packaging and has a high market demand. |

|

The paper properties of the two are actually the same, with the main difference being the surface coating process. Essentially, they are composed of a surface layer, a lining layer, a core layer, and a bottom layer. Surface layer: mainly produced from bleached wood pulp. Lining: In order to ensure the whiteness of the paper surface and save wood pulp raw materials, the white surface will be sandwiched between one or two layers of bleached straw pulp. Core layer: Same as the lining layer. Bottom layer: mainly composed of natural waste paper pulp. |

||

In summary, although both types of paper share similar base performance, the difference in surface coating technology leads to distinct application advantages. Choosing between them depends on specific application needs, budget constraints, and the desired appearance of the final product. Whether pursuing high-end aesthetics or focusing on cost-effectiveness, both types of kraft paper offer suitable solutions to meet diverse market demands.