The global shift toward sustainable packaging has placed paper-based solutions at the forefront of the food and beverage industry. However, raw paper is inherently porous and hydrophilic, meaning it absorbs liquid and loses structural integrity quickly. This is where PE coated cup paper becomes essential.

As a specialized material, it combines the biodegradability of paperboard with the moisture-resistant properties of polyethylene. In this guide, we will explore the technical specifications, manufacturing processes, and safety standards that make PE coated paper the industry standard for disposable cups.

What is PE Coated Paper for Paper Cups?

At its core, PE coated paper for paper cups is a composite material consisting of a high-quality paper base (usually wood pulp) bonded with a thin layer of polyethylene (PE) plastic. This coating acts as a functional barrier, transforming a simple piece of cardboard into a liquid-proof vessel.

Defining the Components

- Base Paper (Substrate): Typically made from virgin wood pulp, providing the necessary stiffness and “cup-forming” ability.

- Polyethylene (PE) Layer: A thermoplastic polymer applied through an extrusion process. It provides the water-resistant, grease-proof, and heat-sealing properties required for cup assembly.

Technical Classification of PE Coating

Manufacturers categorize this material based on the side of the coating:

- Single-Sided PE (1PE): Used primarily for hot drink cups. The PE is on the inside to hold the liquid.

- Double-Sided PE (2PE): Used for cold drink cups. The coating on both sides prevents the paper from softening due to condensation on the exterior.

What is the Structure of PE Coated Paper?

To understand how this material functions, we must look at it from a microscopic level. The structure is not merely a “sticker” applied to paper; it is a molecularly bonded multi-layer system.

The Multi-Layer Breakdown

| Layer | Material Type | Primary Function |

|---|---|---|

| Top Layer | Polyethylene (PE) | Provides waterproof barrier and enables heat-sealing. |

| Interface | Bonding Zone | Created through high-temperature extrusion to ensure no delamination. |

| Core Layer | Food Grade Paperboard | Provides mechanical strength, stiffness, and shape retention. |

| Bottom Layer | PE or Surface Treatment | Optional (in 2PE) for condensation resistance or printability. |

Quantifying Polyethylene Coating Thickness

The performance of the cup depends heavily on the polyethylene coating thickness. In the industry, this is measured in grams per square meter (gsm).

- Standard inner coating: 12g to 18g/m².

- Heavy-duty coating: 20g+ /m² for large-capacity or high-grease contents.

The precision of this thickness ensures that the cup can be heat-sealed at high speeds without the plastic melting away or being too thin to prevent “wicking” (liquid seeping into the paper fibers).

How Does PE Coating Prevent Liquid Leakage in Paper Cups?

The primary challenge for any paper cup is maintaining a “dry” exterior while holding a “wet” interior. PE coating solves this through three distinct mechanisms:

1. Surface Tension and Hydrophobicity

Polyethylene is naturally hydrophobic. When hot coffee or cold soda is poured into a pe coated paper cup, the liquid sits on top of the plastic layer. Because the PE has very low surface energy, the water molecules cannot penetrate the barrier to reach the cellulose fibers of the paper.

2. Heat-Seal Integrity

Traditional adhesives often fail under high heat. PE coated paper utilizes the thermoplastic nature of the coating itself. During the cup-forming process, high-frequency heat or hot air melts the PE edges, fusing them together. This creates a seamless weld at the side seam and the bottom rim, which are the most common points of leakage.

3. Resistance to Capillary Action

Paper is made of fibers that naturally pull liquid in through capillary action. By applying an even food grade pe coated paper layer, the “pores” of the paper are completely sealed. This prevents “wicking,” where liquid travels up the walls of the cup and makes the rim soggy.

Why is Food Grade PE Coated Paper Essential for Safety?

When dealing with food contact materials, “ordinary” plastic is not sufficient. There is a strict distinction between industrial PE and food grade pe coated paper.

Regulatory Compliance and Standards

For a material to be labeled as food contact pe coated paper, it must meet international safety benchmarks:

- FDA Approval: Must be fda approved pe coated paper, ensuring no harmful chemicals migrate from the plastic into the beverage.

- Migration Limits: Testing ensures that even at boiling temperatures (100°C), the polyethylene does not release monomers or additives.

- Sensory Neutrality: The coating must not alter the taste or odor of the drink.

Key Certifications to Look For

- FDA (USA): 21 CFR 177.1520 compliance.

- EU 10/2011: Specific migration limits for plastic materials in contact with food.

- GB 4806 (China): National safety standards for food-related paper products.

What are the Different Types of Polyethylene Used in Coating?

Not all PE coatings are created equal. The choice of polymer affects the cup’s flexibility and heat resistance.

LDPE (Low-Density Polyethylene)

This is the most common choice for pe coated paper for paper cup production.

- Pros: High flexibility, excellent sealing properties at lower temperatures, and cost-effective.

- Best for: Standard coffee cups and fast-food soda cups.

HDPE (High-Density Polyethylene)

While less common, HDPE is used for specialized applications.

- Pros: Higher melting point and better chemical resistance.

- Best for: Industrial packaging or cups containing highly acidic or oily liquids.

What is the Step-by-Step Manufacturing Process?

The production of pe coated cup paper is a high-tech extrusion process that requires precision to ensure the paper does not burn while the plastic remains molten enough to bond.

Phase 1: Material Preparation

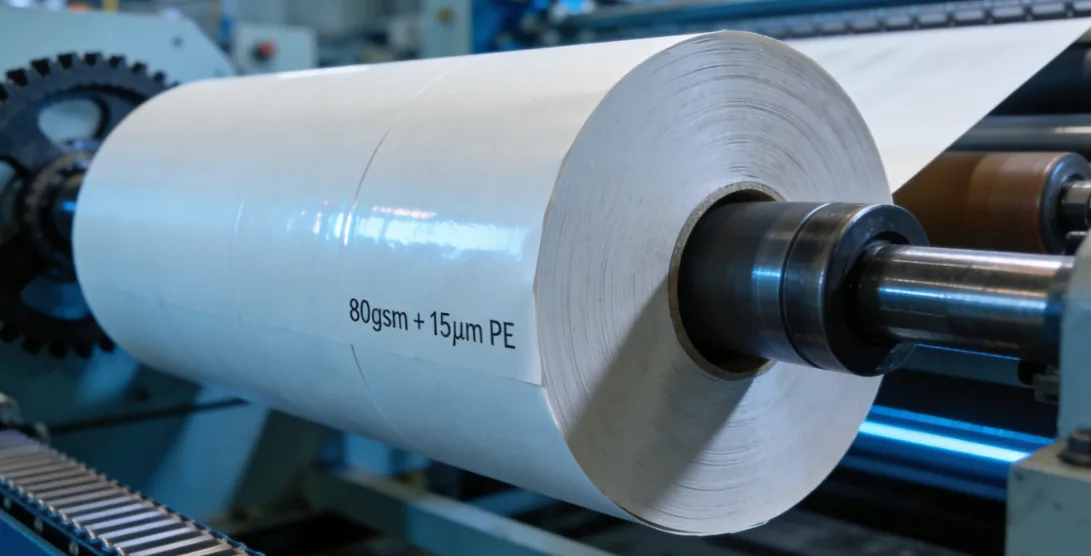

The base paper is loaded into a jumbo roll. The moisture content of the paper must be strictly controlled (usually between 4% and 6%) to prevent bubbling during the coating phase.

Phase 2: Extrusion Coating

- Melting: PE resin pellets are fed into an extruder and heated to approximately 280°C – 320°C.

- Die Casting: The molten PE is pushed through a T-die, creating a thin, consistent “curtain” of liquid plastic.

- Lamination: The paper travels at high speeds (up to 300m/min) and meets the PE curtain between two rollers: a “chill roll” and a “pressure roll.”

- Bonding: The pressure roll forces the PE into the microscopic pores of the paper, while the chill roll instantly solidifies it.

Phase 3: Slitting and Rewinding

The wide jumbo rolls are slit into smaller “web” widths based on the specific template of the paper cup fans.

What Common Problems Occur with PE Coated Paper?

Even with advanced machinery, certain technical failures can lead to defective cups. Understanding these helps in quality control.

| Problem | Cause | Solution |

|---|---|---|

| Poor Adhesion (Peeling) | Extrusion temperature too low or paper too moist. | Increase melt temperature or pre-treat paper with Corona treatment. |

| Pinholes | Dust on the paper or uneven polyethylene coating thickness. | Improve clean-room standards and calibrate the T-die. |

| Odor in the Cup | Overheating of the PE resin during extrusion. | Reduce the residence time of resin in the extruder. |

| Leakage at Bottom | Insufficient PE thickness for heat sealing. | Adjust GSM of PE coating to 15g or higher. |

FAQ: Key Insights into PE Coated Cup Paper

Why is PE coating preferred over wax for modern paper cups?

Unlike wax, which can melt into hot drinks and has poor durability, PE coating offers a permanent bond that withstands boiling temperatures. PE also allows for high-speed automated heat-sealing, which is impossible with wax-coated surfaces, making it more efficient for mass production.

Can PE coated paper cups be recycled easily?

Recycling PE coated paper is possible but requires specialized “hydro-pulping” facilities. These plants separate the plastic lining from the high-quality paper fibers. While more complex than standard paper recycling, many regions are expanding infrastructure to recover these valuable wood fibers.

What is the difference between 1PE and 2PE coating?

1PE (Single-sided) has one layer of plastic on the inside, ideal for hot drinks where the outside remains dry. 2PE (Double-sided) adds a layer to the exterior. This is crucial for cold drinks because it prevents external condensation from soaking into the paper and weakening the cup.

Is PE coated paper safe for microwave use?

Generally, standard PE coated cups are not recommended for microwave use. The PE coating has a melting point (around 105°C to 115°C). In a microwave, localized “hot spots” in liquids can exceed this temperature, potentially causing the coating to soften or migrate into the food.

How do I choose the right GSM for my paper cups?

The choice depends on the cup size. For a 4oz espresso cup, a 190gsm base + 15g PE is sufficient. For a 16oz large latte cup, you need a thicker 300-320gsm base with an 18g PE coating to ensure the cup doesn’t “bridge” or collapse when held.