In the industrial world of 2025, kraft paper applications have expanded far beyond the traditional grocery bag. From delicate e-commerce interleaving to rugged construction materials, kraft paper is the go-to substrate for businesses seeking durability and sustainability. However, the most critical decision a procurement manager faces is selecting the correct “GSM” (Grams per Square Meter).

Choosing the wrong weight can lead to product damage or unnecessary overhead costs. This comprehensive kraft paper GSM guide will walk you through the technical requirements of various sectors, helping you optimize your packaging strategy for both performance and cost-efficiency.

What Is the Best GSM of Kraft Paper for Void Fill?

In the e-commerce and logistics sectors, protecting items during transit is paramount. Industrial wrapping paper used for void fill—the process of stuffing empty spaces in a box to prevent movement—requires a specific balance of flexibility and “crumple” volume.

The Ideal Weight for Protection

For standard void fill applications, the industry standard is 60 GSM to 80 GSM.

- Why this range? Paper below 60 GSM is often too thin to maintain its shape when crumpled, losing its cushioning properties. Paper above 90 GSM becomes too stiff, making it difficult for packers to handle and potentially scratching delicate surfaces.

- Performance Factor: At 70 GSM, kraft paper provides optimal “spring-back” tension, absorbing shocks during the shipping process without adding significant weight to the parcel.

Comparison: Void Fill vs. Interleaving

| Application | Recommended GSM | Primary Goal |

|---|---|---|

| Void Fill | 70 – 90 GSM | Cushioning and blocking movement |

| Interleaving | 35 – 50 GSM | Preventing surface scratches (e.g., between glass or metal sheets) |

| Surface Protection | 100+ GSM | Heavy-duty protection for floors or large machinery |

Is Kraft Paper Safe for Direct Food Contact?

The food service industry is one of the largest consumers of food grade kraft paper for packaging. However, not all kraft paper is created equal when it comes to hygiene and safety standards.

Ensuring Food Safety

To be considered safe for direct contact, the paper must be “Virgin Kraft”—meaning it is made from 100% new wood pulp rather than recycled fibers, which may contain traces of inks or chemicals.

- Certifications: Look for FDA (U.S.), BfR (Germany), or GB (China) food-safe certifications.

- Barrier Needs: For greasy foods like pastries or fried snacks, businesses often use food grade kraft paper with a light greaseproof treatment or a thin PE/PLA coating (typically 40 GSM base + 10 GSM coating).

Common GSM for Food Applications

- Flour/Sugar Bags: 80 – 110 GSM (multi-wall)

- Bread/Bakery Bags: 35 – 50 GSM

- Fast Food Wraps: 28 – 45 GSM

Which Type of Kraft Paper is Strongest for Heavy Items?

When dealing with industrial equipment, automotive parts, or bulk chemicals, strength is non-negotiable. For these sectors, high burst strength kraft paper for shipping is the technical requirement.

Key Strength Metrics

Strength in kraft paper isn’t just about thickness; it’s about the Mullen Burst Test results and Tensile Energy Absorption (TEA) .

- Heavy-Duty Brown Kraft Paper Rolls: Typically range from 125 GSM to 300 GSM. These are used for wrapping metal rods, furniture, or as liners for shipping containers.

- Sack Kraft Paper: This is a specialized high-porosity paper (usually 70-100 GSM) used in multi-wall bags for cement or flour. Its strength comes from its ability to stretch slightly rather than tear when dropped.

Reinforced Solutions

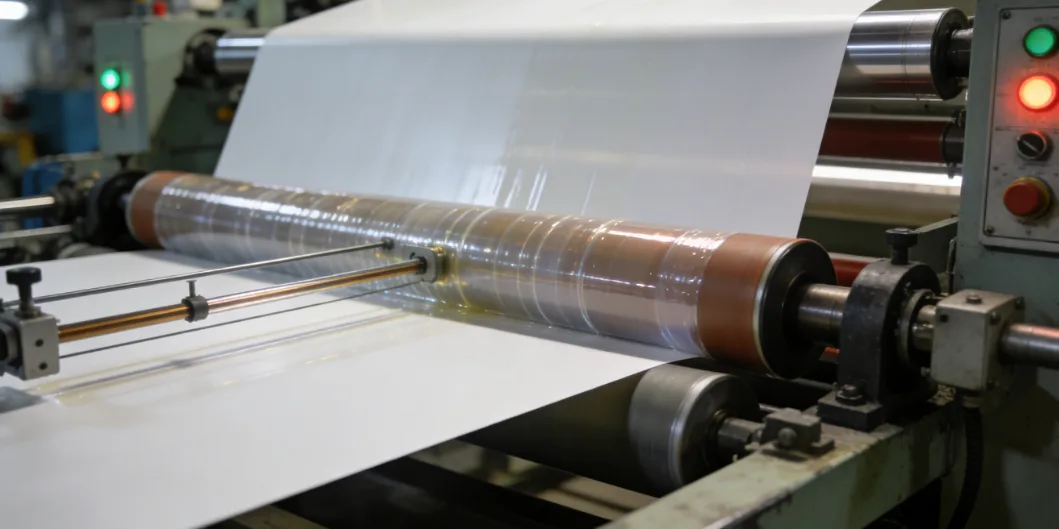

For the most extreme logistics challenges, businesses use “Scrim-Reinforced” kraft paper. This involves laminating a fiberglass or polyester mesh between two layers of 60 GSM kraft paper, creating a material that is virtually impossible to tear by hand.

How to Choose Between Bleached and Unbleached Kraft Paper?

The choice between brown (unbleached) and white (bleached) kraft paper usually comes down to a trade-off between kraft paper applications and branding requirements.

Unbleached (Natural) Kraft Paper

- Pros: Stronger fibers (the bleaching process slightly weakens the cellulose), more eco-friendly, and cost-effective.

- Best For: Industrial wrapping paper, shipping liners, and brands wanting a “rustic” or “organic” look.

Bleached (White) Kraft Paper

- Pros: Provides a clean, medical-grade appearance and a superior canvas for custom printed kraft paper for branding.

- Best For: High-end retail bags, flour sacks where “purity” is a visual cue, and pharmaceutical packaging.

What Industries Use Kraft Paper the Most?

Kraft paper’s versatility makes it a staple across diverse global markets. Here is how different sectors utilize this material in 2025:

1. E-commerce and Retail

Uses custom printed kraft paper for branding to create a premium unboxing experience. Lightweight 50-70 GSM paper is used for wrapping products, while 120+ GSM is used for premium shopping bags.

2. Agriculture and Construction

Relies on multi-wall sacks (multiple layers of 80 GSM kraft) to transport seeds, fertilizers, and cement. The breathable nature of the paper prevents mold in agricultural products.

3. Manufacturing and Metalworking

Uses VCI (Volatile Corrosion Inhibitor) treated kraft paper. This specialized industrial wrapping paper releases a vapor that prevents rust on steel and aluminum parts during overseas shipping.

FAQ: Industrial Selection and Specifications

What is the most common GSM for standard shipping boxes?

While boxes are made of corrugated fiberboard, the “linerboard” (the flat surface) is usually made of kraft paper ranging from 125 GSM to 250 GSM. The higher the GSM of the liner, the higher the stacking strength of the box.

How does GSM affect the cost of wholesale kraft paper?

Generally, kraft paper is sold by weight (metric tons). Therefore, using a higher GSM than necessary increases your cost per square meter. Moving from 90 GSM to 70 GSM for void fill can reduce your material costs by over 20% while still providing adequate protection for light items.

Can I get custom printed kraft paper for branding in heavy weights?

Yes. Custom printed kraft paper for branding is available across the entire GSM spectrum. For heavy-duty rolls (150+ GSM), flexographic printing is commonly used to ensure the ink penetrates the dense fibers without compromising the paper’s integrity.

Is high burst strength kraft paper for shipping recyclable?

Absolutely. As long as the paper is not laminated with plastic or heavily coated with wax, even the heaviest heavy-duty brown kraft paper rolls are 100% recyclable and are highly valued by paper mills for their long, strong fibers.

Why is kraft paper preferred over plastic for industrial wrapping?

Beyond sustainability, kraft paper offers better friction (preventing pallets from sliding), breathability (preventing condensation), and superior puncture resistance against sharp metal edges compared to standard plastic stretch film.