In the specialized field of paper packaging, the distinction between Duplex Board and Ivory Board is not merely a matter of terminology; it is a fundamental choice that dictates the cost, durability, and perceived value of a finished product. For businesses aiming to optimize their supply chain and packaging aesthetics, understanding these two substrates is critical.

This article provides an in-depth, technical comparison of Duplex Board and Ivory Board, focusing on their material composition, printing performance, and industrial suitability.

What are the Definitions of Duplex Board and Ivory Board?

Before evaluating their differences, we must define the unique properties that categorize these two materials.

What is Duplex Board (Coated Duplex)?

Duplex Board is a multi-layered paperboard manufactured from recycled fibers and waste paper.1 The term “duplex” refers to its two distinct layers: a smooth, white-coated top surface and a functional back layer.2

- Grey Back Duplex (GD2/GD3): Features a grey interior and back, made from recycled newsprint or mixed waste.

- White Back Duplex (GT1/GT2): Features a white or cream-colored back for a cleaner look while still utilizing a recycled core.

What is Ivory Board (SBS/FBB)?

Ivory Board, also known as Folding Boxboard (FBB) or Solid Bleached Sulfate (SBS) , is a premium-grade substrate made from 100% virgin chemical pulp.3 It is a single-ply or multi-ply board that is bleached throughout, ensuring that the interior of the board is as white as the exterior. It is renowned for its high density, stiffness, and superior whiteness.4

Technical Comparison: Duplex Board vs. Ivory Board

The following table summarizes the key performance indicators (KPIs) and technical specifications of both boards.

| Technical Metric | Duplex Board (Grey/White Back) | Ivory Board (Premium SBS/FBB) |

|---|---|---|

| Raw Material | Recycled Pulp (Post-consumer waste) | 100% Virgin Wood Pulp |

| Whiteness (CIE) | 75% – 85% (Top side only) | 90% – 95%+ (Through-and-through) |

| Surface Finish | Coated Top / Rough Back | Smooth Coated Top / Matte Back |

| Density & Stiffness | Moderate to Low | Superior / High Rigidity |

| Thickness (Caliper) | 0.30mm – 0.60mm | 0.25mm – 0.55mm |

| Food Safety | Not recommended for direct contact | Food Grade (Safe for direct contact) |

| Typical GSM | 230gsm – 450gsm | 190gsm – 400gsm |

| Cost Profile | Economical / Budget-friendly | Premium / Higher Investment |

How Does Material Composition Impact Performance?

The primary “fact point” that separates these two is the fiber origin. This structural difference leads to three major performance gaps:

1. Structural Integrity and Folding Endurance

Because Ivory Board is made from virgin long-fiber pulp, it possesses excellent folding endurance. When an Ivory Board box is creased and folded, the fibers remain intact, preventing the “cracking” often seen on the edges of lower-quality boxes.5 Duplex board, being made from shorter recycled fibers, is more brittle and may require lamination (like a plastic film) to prevent the printed surface from cracking at the folds.

2. Ink Absorption and Color Fidelity

Ivory Board has a more consistent and refined coating layer. This allows for low ink absorption (high ink holdout) , meaning the ink stays on the surface to produce vivid, high-contrast colors. Duplex board, while printable, has a more porous top layer, which can lead to “dot gain”—a phenomenon where ink spreads slightly, causing images to look less sharp than they would on Ivory Board.6

3. Safety and Hygiene Standards

Fact: Ivory Board is the gold standard for pharmaceutical and food packaging.7

Since it contains no recycled content, there is zero risk of mineral oil or chemical migration from old newsprint (a common issue in recycled duplex board). If your product touches the paper directly—such as a cake, a burger, or a pill—Ivory Board is the required choice for compliance with FDA or EU food safety regulations.8

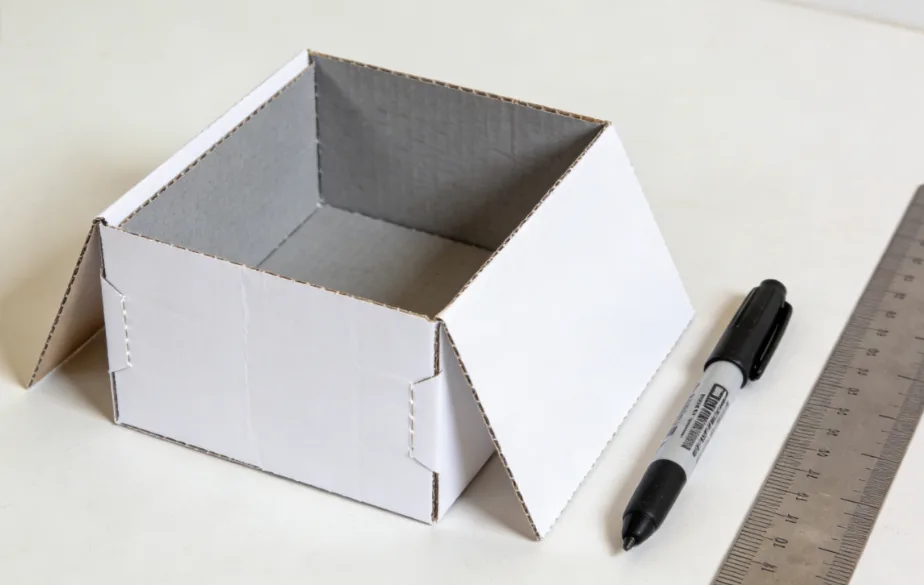

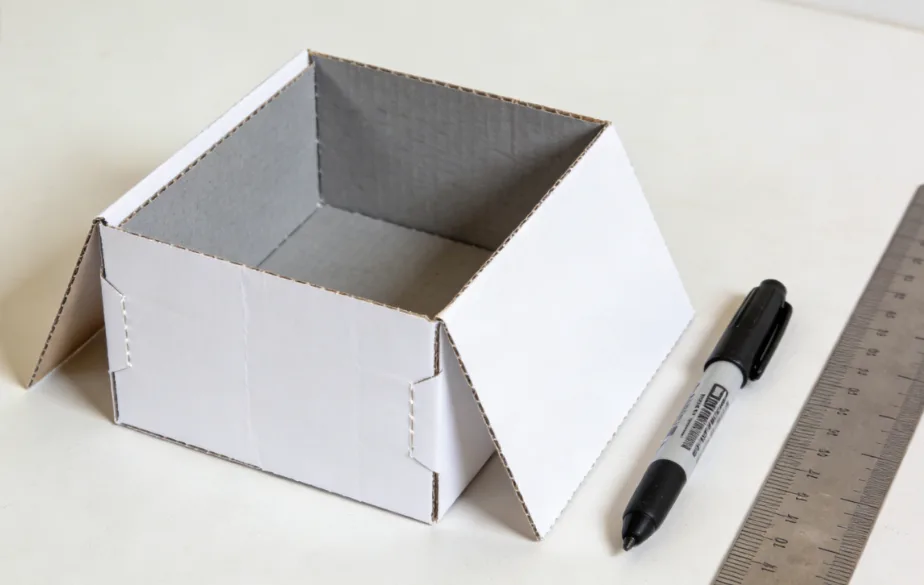

Step-by-Step: How to Choose Between Duplex and Ivory Board

When deciding on a material for your project, follow this logical workflow to ensure you balance cost with quality:

-

Analyze the Product Weight:

- If the product is heavy (e.g., hardware, heavy electronics), choose a high-GSM Duplex Board for cost-effective strength.

- If the product is light but premium (e.g., cosmetics, jewelry), choose Ivory Board for its sleek feel.

-

Determine the Visual Identity:

- Does the brand require “Pure White” packaging? If yes, Ivory Board is mandatory because the “Grey Back” of duplex board can be seen at the edges and inside the box.

-

Evaluate the Environmental Goals:

- If “Recycled Content” is your primary marketing claim, Duplex Board is the winner.9

- If “Sustainable Forestry (FSC)” and high-end durability are the goals, Ivory Board is the better fit.

-

Consider the Budget:

- For mass-market FMCG (Fast Moving Consumer Goods) like soap boxes or toothpaste, Duplex Board provides the necessary protection at a fraction of the price.10

Practical Applications in Different Industries

The Domain of Duplex Board

- Shoe Boxes: Requires volume and protection, but the “inside” look is less critical.

- Matchboxes and Small Hardware: Items where the cost of packaging must be kept extremely low.

- Cereal Boxes: Traditional high-volume food packaging (usually with an inner plastic liner).

The Domain of Ivory Board

- Luxury Cosmetic Packaging: Perfume and skincare boxes demand the “hand-feel” of high-stiffness Ivory Board.11

- Greeting Cards & Invitations: The high whiteness and smooth texture are essential for a premium tactile experience.12

- Medical & Pharmaceutical Cartons: Where clarity of fine-print instructions and hygienic purity are paramount.

Frequently Asked Questions (FAQ)

Is Ivory Board more eco-friendly than Duplex Board?

It depends on your definition of “eco-friendly.” Duplex Board is superior for resource conservation as it uses recycled waste paper.13 However, Ivory Board is often sourced from FSC-certified sustainable forests, is easier to recycle again after use, and is free from toxic ink residues found in some recycled materials.

Can I print on the back of a Duplex Board?

Printing on the “Grey Back” of a duplex board is generally not recommended for high-quality graphics. The grey surface absorbs ink heavily, making colors appear muddy and dark. If you need double-sided printing, you should opt for White Back Duplex or, ideally, Art Board (C2S) .

Why is Ivory Board often called FBB or SBS?

These are technical industry terms. FBB (Folding Boxboard) usually refers to a multi-ply board with a mechanical pulp center, providing high bulk.14 SBS (Solid Bleached Sulfate) is a premium, high-density board made entirely of bleached chemical pulp. In many markets, both are colloquially marketed as “Ivory Board.”

Does Ivory Board turn yellow over time?

Ivory Board is highly resistant to yellowing because it is made from bleached chemical pulp, which has the lignin removed. Duplex board, which contains mechanical pulp and recycled fibers (with higher lignin content), will yellow significantly faster when exposed to UV light or heat.

Which board is better for special finishes like Embossing?

Ivory Board is significantly better for embossing and debossing. Its long virgin fibers allow the board to stretch and hold a deep, crisp shape without tearing. Duplex board is more likely to crack or produce a “fuzzy” edge when subjected to deep embossing.