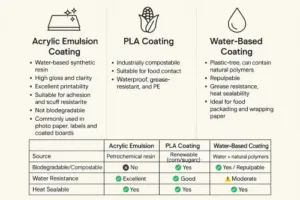

As sustainability and performance continue to shape the Paper packaging industry, manufacturers and buyers alike are exploring alternatives to traditional plastic coatings. Among the most popular coating options today areAcrylic Emulsion Coating, PLA Coating, and Water-Based Coating.

But what are the differences between these three materials? Which one is best suited for your packaging needs? Let’s break it down:

✅ 1. Acrylic Emulsion Coating

What it is:

Acrylic emulsion is a water-based synthetic resin made from petroleum-derived polymers. It is applied to paper surfaces to enhance gloss, printability, and water resistance.

Key Features:

- High gloss and clarity

- Excellent printability

- Strong adhesion and scuff resistance

- Commonly used in photo paper, labels, and Coated boards

- Not biodegradable or compostable

- Relatively high cost due to resin content

Best for:

High-end print applications, advertising materials, and packaging that requires durability and appearance.

✅ 2. PLA Coating

What it is:

PLA (Polylactic Acid) is a bioplasticmade from renewable resources such as corn starch or sugarcane. When used as a paper coating, it offers good barrier properties and isindustrially compostable.

Key Features:

- 100% compostable under industrial conditions

- Suitable for food contact

- Acts as a waterproof and grease-resistant layer

- Requires higher coating weight than PE to achieve the same barrier effect

- More sensitive to temperature and sealing conditions

Best for:

Eco-friendly paper cups, bowls, and other food-grade disposable packaging where sustainability is a key concern.

✅ 3. Water-Based Coating

What it is:

This type of coating uses water as the main solvent and may contain natural polymers (such as modified starch, PVA, or biodegradable resins). It’s designed to provide grease resistance, heat sealability, and printability without plastic.

Key Features:

- Plastic-free and repulpable

- Ideal for food packaging and wrapping paper

- Lower barrier performance than PLA or PE, but improving with new formulas

- Excellent for customers seeking PFAS-free, eco-conscious options

- Usually has a matte or soft finish

Best for:

Greaseproof paper, burger wraps, paper cups, and plastic-free packaging solutions.