Hot Sales

- Home

- Hot Sales

Industrial Ivory Board

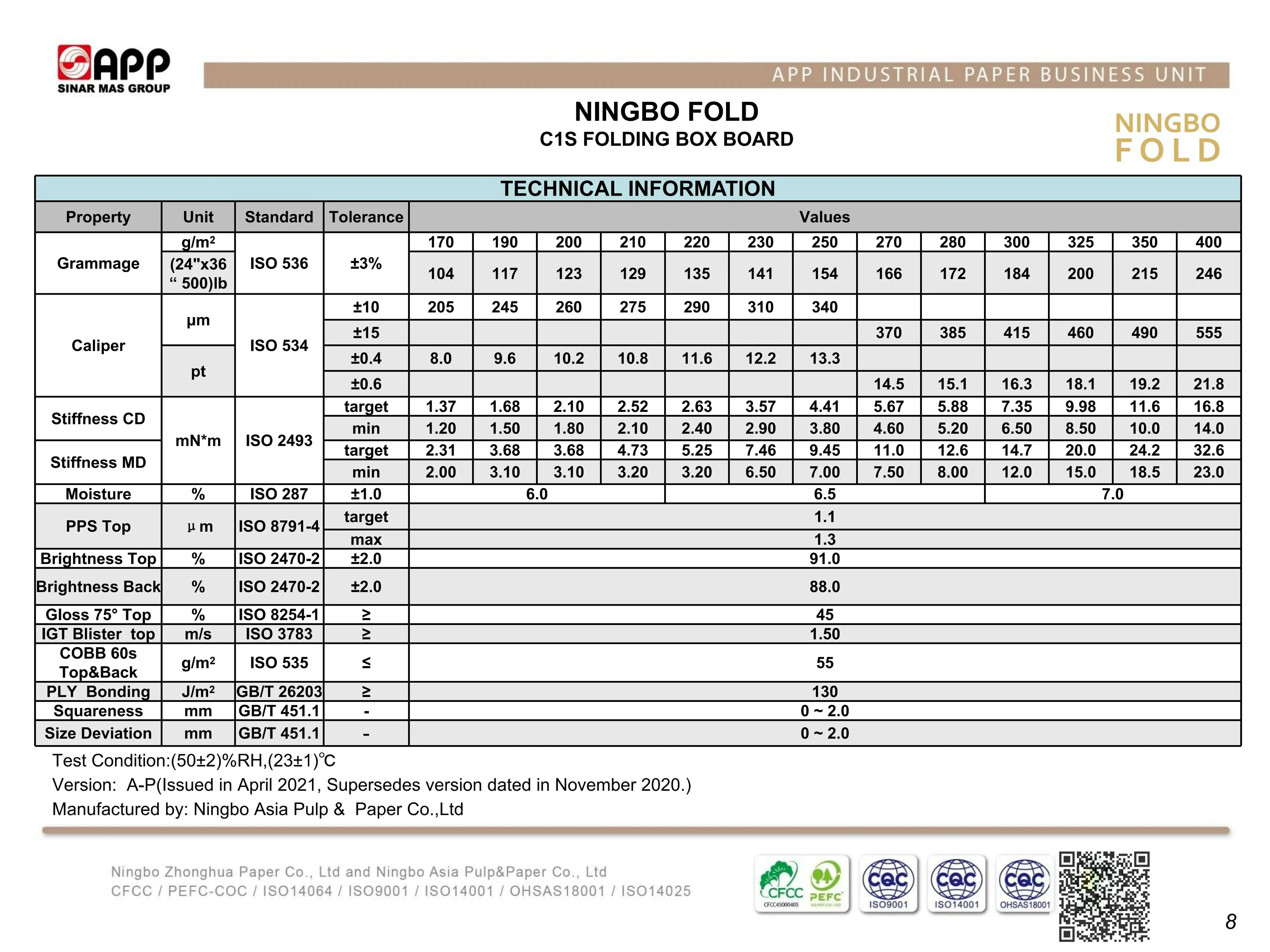

Most of the paper packaging we come into contact with is industrial white cardboard, also known as FBB (FOLDING BOX BOARD), which is a single-layer or multi-layer combined paper that is wholly made of bleached chemical pulp and full-sized. It is suitable for the Printing and packaging of products characterized by high smoothness, good stiffness, clean appearance, and good formation. C1S Ivory board has very high requirements for whiteness. There is A, B, and C three grades according to the different whiteness. The whiteness of grade A is not less than 92%, the whiteness of grade B is not less than 87%, and the whiteness of grade C is not less than 82%. Due to different paper mills and different usages, FBB is divided into many brands, and ivory board at different prices also correspond to other final products. The common packaging on the market is basically made of industrial FBB. Among them, the NINGBO FOLD (FIV) produced by the APP paper mill (NINGBO ASIA PULP & PAPER CO., LTD) is the most famous brand, and the others are the IBS, IBC of the BOHUI paper mill. (Now BOHUI PAPER MILL also belongs to the APP group, getting better managed and more stable production every month) The regular GSM of NINGBO FOLD (FIV) is 230gsm, 250gsm, 270gsm, 300gsm, 350gsm, 400gsm. (same price for range 230 – 400 GSM)

High Bulk Industrial C1s Ivory Board

Due to the difference in bulk, FBB can be divided into normal bulk FBB and high bulk FBB. Due to the thickness requirements of packaging cardboard in different regions, the bulk difference mainly depends on the difference of the market. The bulk of normal bulk FBB is generally around 1.28. The bulk of high-bulk FBB such as IBM, IBH, and IBM-P is basically around 1.6. High-bulk FBB has two advantages over normal bulk FBB: one is the high whiteness of the finished paper, and the product grade is high; the other is the high bulk, which has cost advantages for users.

Food Grade Board

Due to the difference in bulk, FBB can be divided into normal bulk FBB and high bulk FBB. Due to the thickness requirements of packaging cardboard in different regions, the bulk difference mainly depends on the difference of the market. The bulk of normal bulk FBB is generally around 1.28. The bulk of high-bulk FBB such as IBM, IBH, and IBM-P is basically around 1.6. High-bulk FBB has two advantages over normal bulk FBB: one is the high whiteness of the finished paper, and the product grade is high; the other is the high bulk, which has cost advantages for users.

Normal Food-Grade Board

FVO is a high bulk food-grade board and has passed QS certification. It is made of wood pulp, without a fluorescent whitening agent, with good stiffness and uniform thickness. The surface is delicate, the printing adaptability is strong, the printing gloss is excellent, the printing dot restoration effect is good, and the printed product is colorful. Good post-processing adaptability, satisfying various packaging processes such as lamination and indentation, good molding, and no deformation. Exceptional paper for lightweight food packaging, which can be used for the packaging of maternal and infant skin care products, feminine products, personal hygiene products, solid food packaging (milk powder, cereals), and other products. The regular gsm of FVO is 215gsm, 235gsm, 250gsm, 275gsm, 295gsm, 325gsm, 365gsm.

GCU (ALLYKING CREAM)

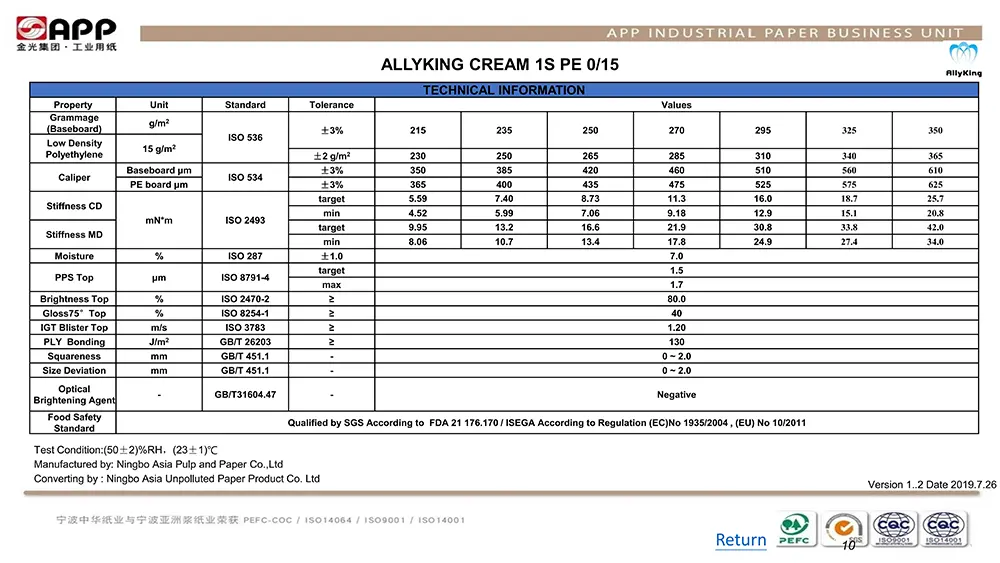

GCU (Allyking Cream) is a high bulk food grade board, which has good printing, processing, and molding performance under ultra-lightweight. Passed QS certification, no fluorescent whitening agent, good stiffness, uniform thickness. It is widely used in the packaging of medicine boxes, daily necessities, etc. that directly contact food, as well as product packaging in a refrigerated and refrigerated environment. It can also be coated with a film to achieve waterproof and moisture-proof effects according to environmental requirements.The regular gsm of GCU is: 215gsm, 220gsm, 235gsm, 240gsm, 250gsm, 270gsm, 295gsm, 325gsm, 350gsm.

CUPSTOCK

It is a food-grade board specially used for making disposable tableware such as paper cups, paper bowls, etc.

FK1 (NATURAL HEARTY –Normal Bulk )

FK0 (NATURAL HEARTY –High Bulk )

FCO

Special paper for lunch boxes, suitable for making all kinds of high-end lunch boxes.

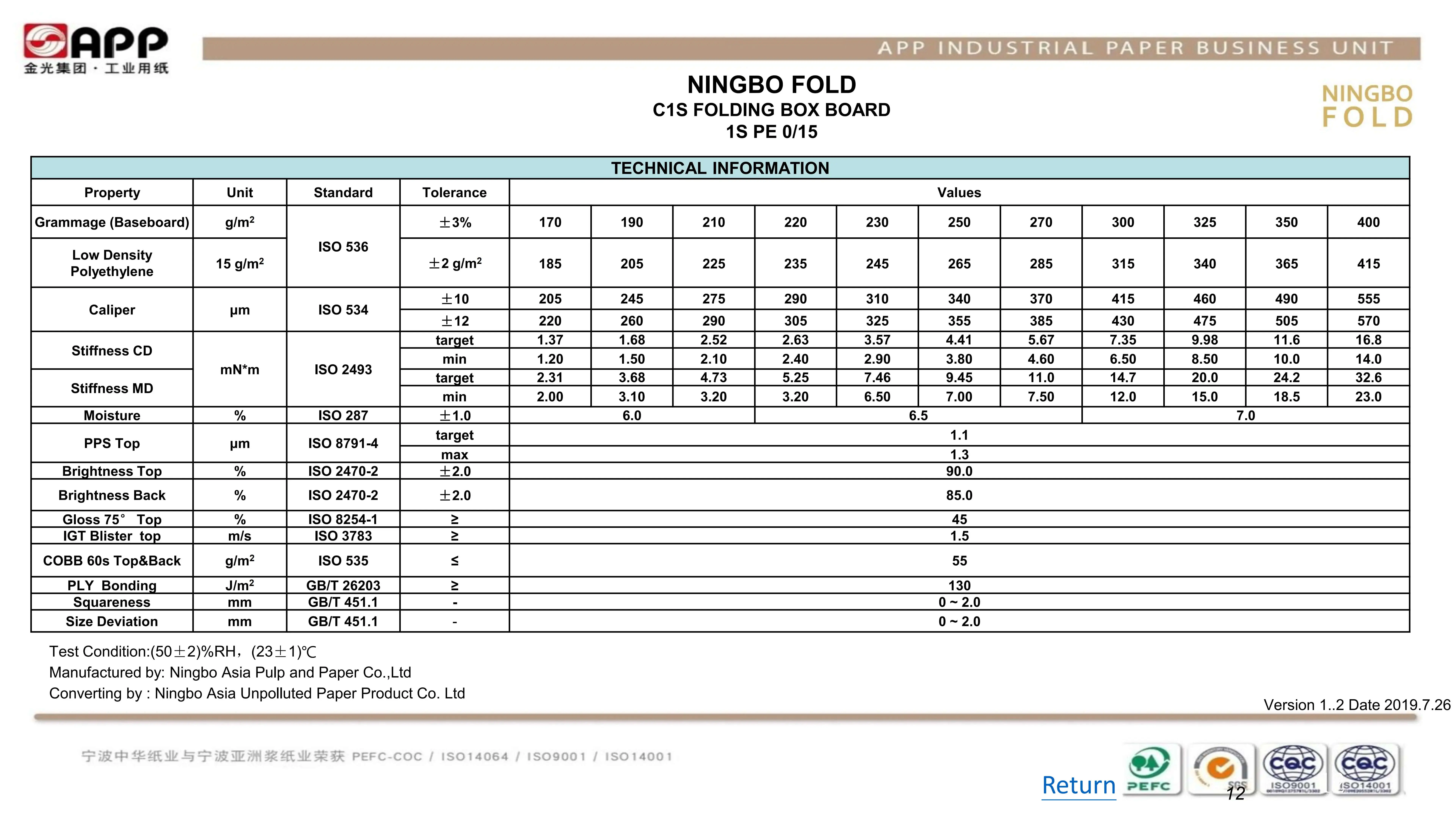

And our end users usually will add PE coating on it, 1 SIDE or 2 SIDE PE (paper TDS attached as below)

The regular gsm:245gsm,260gsm.

Duplex Board

C2S Art Paper/Board

- Forming method: one time forming

- Material: high quality raw material

- Thickness: general

- Paper surface: delicate

- Dimensional stability: good

- Strength/Stiffness: Normal, Internal Bonding: Good

- Main application: picture book

The regular gsm of art paper: 80gsm, 90gsm, 100gsm, 128gsm, 158gsm, 200gsm, 250gsm, 300gsm. (It means for gsm from 80 – 300 gsm art paper can be in glossy or matte)

Characteristics Of Coated Board

- Forming method: one-time molding and multiple molding together, generally three layers

- Material: cheap fiber can be used in the middle

- Thickness: Thick

- Paper surface: slightly rough

- Dimensional stability: slightly worse

- Strength/Stiffness: Strong, Internal Bonding: slightly worse

- Main application: package

The regular gsm of C2S art board: 210gsm, 230gsm, 250gsm, 260gsm, 280gsm, 300gsm, 310gsm, 350gsm, 360gsm, 400gsm. (Art board over 300 gsm can only in gloss, no matte)

Offset paper

Offset paper

Carbonless copy paper is a kind of leuco copy paper, which has the functions of direct copying and direct color development. Its color development is mainly: under the action of external force, the force-sensitive pigment and oil solution in the microcapsules overflow and contact with the color developer to cause a dyeing reaction, thereby playing the role of copying. It is mainly used for multiple forms, bills, continuous financial notes, general business financial notes, etc.

There are two coatings in carbonless copy paper: a CF layer containing a chromogenic agent and a CB layer containing a chromogenic agent. The chromogenic agent is a special colorless dye that has been dissolved in non-volatile carrier oil and encapsulated by microcapsules of 3-7 μm. The impact pressure of forceful writing and printing can crush the microcapsules, allowing the colorless dye solution to flow out and contact the color developer, and a chemical reaction occurs to present colored graphics, thereby achieving the purpose of copying. Carbonless copy paper is divided into 45g/m2CB paper, 47g/m2CF paper and 52g/m2CFB paper according to the quantity; according to the color of the paper, there are five types: red, yellow, green, blue, and white; according to the color traces, there are blue, Yellow, orange, black, red and other colors.

Carbonless copy paper is mostly used on documents. The existing formal documents with legal effect such as invoices, contracts and treaties have all used carbonless copy paper. Traditional receipts are just ordinary paper, so it is necessary to add a carbon layer under the receipt. The carbonless copy paper is bound with special paper.