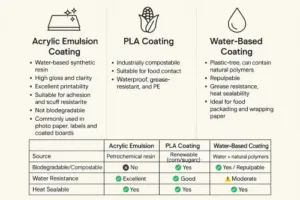

Several factors come into play when comparing polyethylene(PE) coating to water-based coating, including cost-effectiveness, performance and environmental impact.

Polyethylene coatings offer a simple and cost-effective solution, while water-based coatings offer a more sustainable alternative with their biodegradable properties.

Both coatings have their advantages and disadvantages and the choice depends on various factors such as intended use, cost considerations and environmental impact.

Balancing Cost and Performance:

When deciding between PE and water-based coatings, cost efficiency and performance play a crucial role.

PE coating offers a cost-effective solution with its easy application and strong adherence, making it a low-cost option for manufacturers. This allows for the production of durable paper cups at a lower cost.

On the other hand, water-based coatings reduce material usage by being absorbed into paper fibers, potentially leading to long-term cost savings. However, they generally involve higher upfront costs compared to PE coatings.

A thorough cost-benefit analysis is essential to determine which type of coating provides the best balance between immediate costs and long-term environmental benefits

Influence on Recycling and Waste Management:

When considering the impact of coatings on recycling and waste management, it’s important to note the following key points:

PE Coated paper presents challenges for recycling due to its non-biodegradable and non-compostable nature. Separating the PE layer from the paper fibers is labor-intensive, often resulting in most PE coated paper being sent to landfills.

In contrast, water-based coatings offer a more environmentally friendly solution as they are biodegradable and compostable. Innovative recycling-friendly coatings, are designed to integrate more easily into recycling streams, simplifying the recycling process and reducing the environmental footprint.

Overall, water-based coatings present a more sustainable alternative in terms of waste management, offering potential benefits for recycling and reducing the amount of paper cup waste sent to landfills.

Transformative Innovations in Paper Cup Coatings:

The paper cup industry is embracing sustainable changes through innovative coatings. Biodegradable options like PLA and technological advancements are driving progress towards a more sustainable future. These innovations demonstrate a dedication to functionality and environmental conservation, leading to a reduction in plastic packaging.

Revolutionary Developments in Biodegradable Coatings:

Biodegradable coatings, such as PLA, are offering an eco-friendly alternative to traditional plastic coatings and films. Derived from renewable resources like corn starch, PLA coatings are food grade, biodegradable, compostable, and exhibit high strength and resistance to tear, heat, water, and grease.

Next-generation biodegradable cups featuring PLA coatings are setting new industry standards for degradability and reduced carbon footprints. The growing consumer preference for sustainable food packaging is fueling the demand for environmentally responsible choices, making PLA-coated paper cups a popular option.

Summary

In conclusion, the choice between PE and water-based coatings for paper cups involves balancing performance, cost, and environmental impact.

PE coatings offer durability and cost-effectiveness but have significant environmental drawbacks.

Water-based coatings provide a sustainable alternative with biodegradable properties and a reduced environmental footprint.

Innovations in biodegradable coatings and technology are driving eco-friendly solutions in the paper cup industry.

As consumer demand for sustainability grows, brands prioritizing environmentally friendly practices will thrive. Together, we can create a more sustainable future, one paper cup at a time.