September 2025 · Industry News · Print & Packaging Materials

TrendAs production costs rise and sustainability requirements tighten, light-weight coated paper (LWC) is becoming a preferred material for publishers, advertisers and packagers seeking a practical balance between cost and visual quality.

What is LWC?

Light-weight coated paper(LWC) is manufactured by applying a thin, uniform coating of pigments and binders onto a base paper. This thin coating yields a smooth printing surface that reproduces color and detail well while keeping the paper’s basis weight low — offering a middle ground between fully Coated art paper and uncoated offset stocks.

Why the industry is paying attention

- Cost efficiency: Lower grammage reduces raw material consumption and shipping weight, delivering measurable savings for large print runs.

- Good print performance: Improved surface smoothness and opacity support crisp text and vibrant images, including reliable double-sided printing.

- Sustainability: Many LWC grades are produced with reduced optical brighteners and processes that lower environmental impact.

- Reader comfort: Select LWC stocks are optimized to reduce glare and eye strain for long-form reading.

Common applications

LWC‘s versatility makes it suitable for a range of products:

- Publishing: Magazines, catalogs, children’s books and educational materials.

- Advertising: Brochures, flyers, direct mail and product catalogues.

- Packaging: Lightweight boxes, inserts, manuals and point-of-sale materials.

- Office & maps: Cost-sensitive prints where decent image quality is required.

Quick technical snapshot

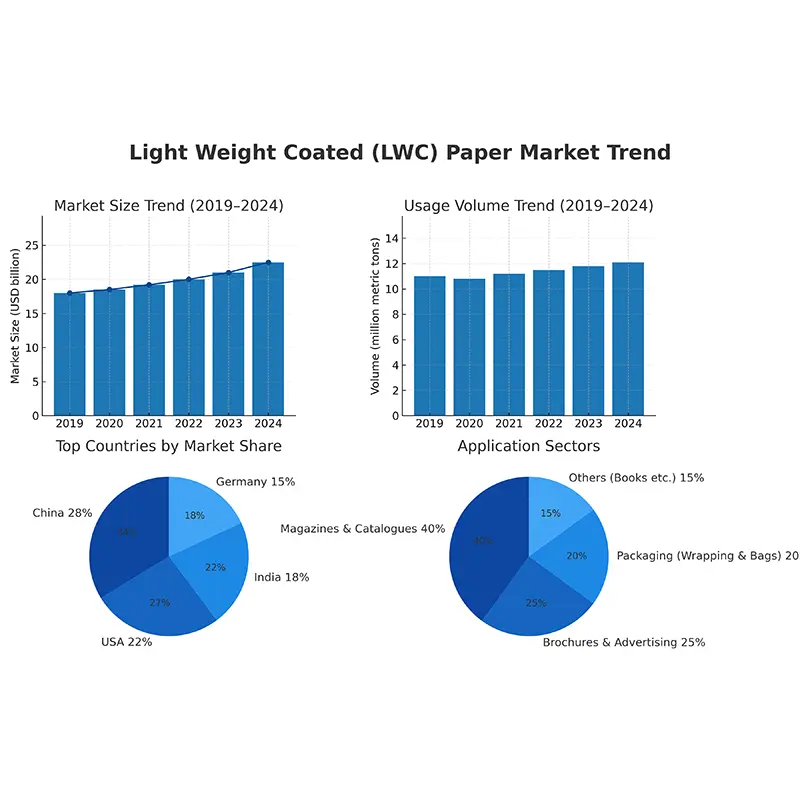

Market outlook

Industry observers note that LWC is well-positioned to expand as brands prioritize both cost control and lower environmental footprints. For printers and converters, LWC offers a practical way to reduce expenses while maintaining the quality expected by consumers.

Considerations for printers

- Test runs are recommended — coating consistency and surface energy affect ink set and dot gain.

- Coordinate with suppliers on available finishes and whether optical brighteners are used.

- Verify runnability on intended press equipment, especially for high-speed web presses and folding operations.