PE Coated Board

- Home

- PE Coated Board

PE Coated Board

Uncoated Food Grade Paper Base

BOHUI – Uncoated Food Grade Paper Base

BOHUI – PCM+PE : Special Paper for Paper Cups

BOHUI – PCB+PE: special paper for paper cups

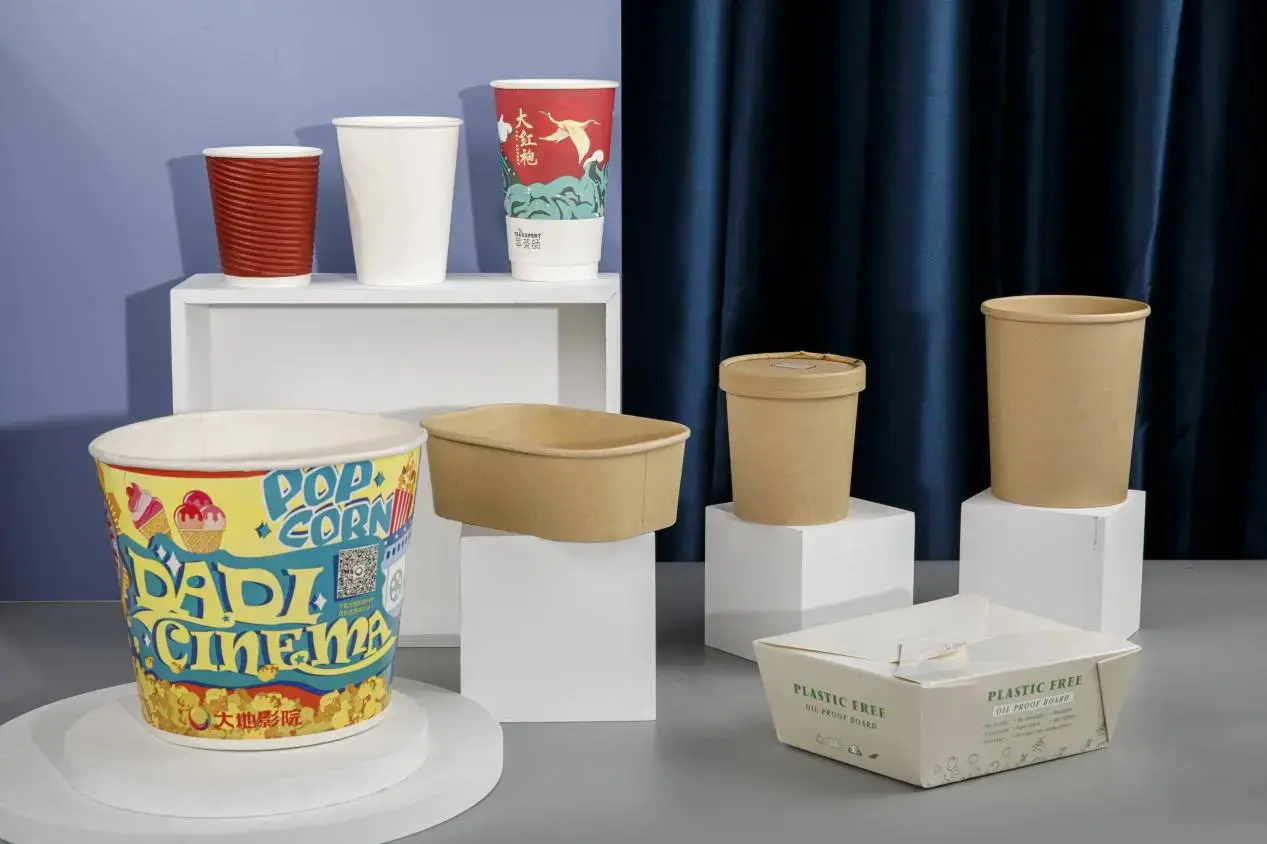

GSM: 210/230/240/280/300/310/320 PCB is also a base paper board without coating. It is specially for high-grade coffee paper cup processing. Here the Chinese local famous brand – Luckin Coffee use this brand with over 1200,000 cups per month. It is enough to prove how good the quality of this paper is.

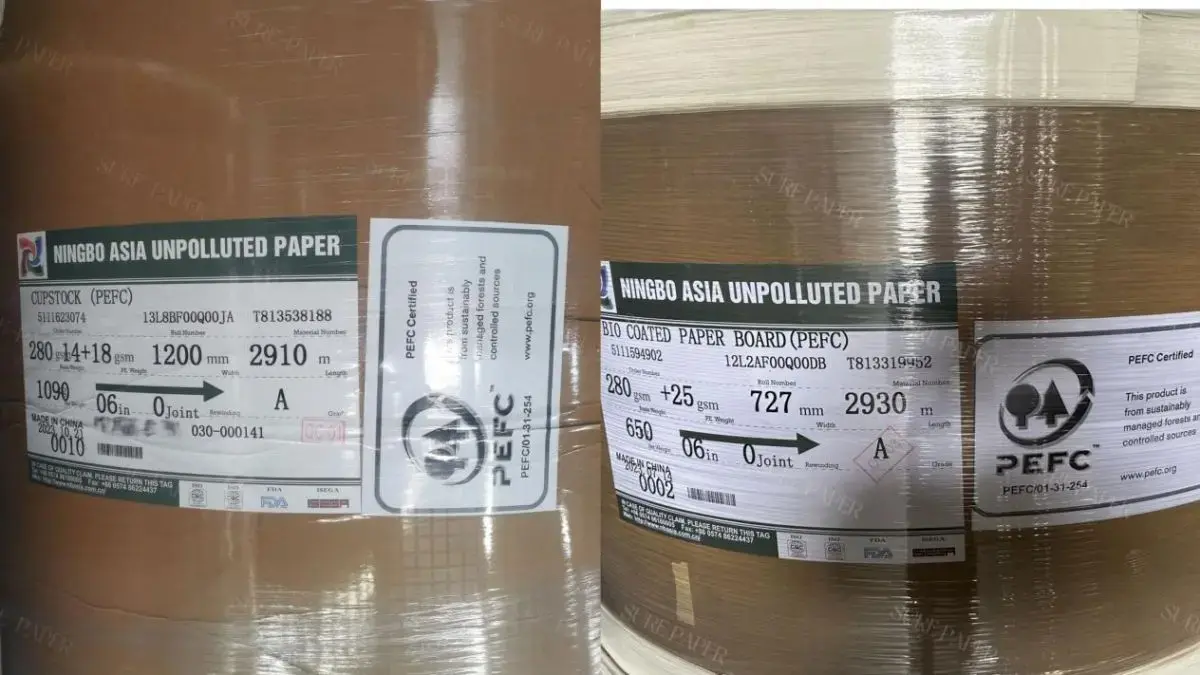

APP – Uncoated Food Grade Paper Base

1. APP -Natural Hearty/FK1+PE: special paper for paper cups GSM: 190/210/230/240/250/260/280/300/300 (normal bulk) FK1 made from all wood pulp, no fluorescent whitening agent, good stiffness, high bulk, no odor, excellent resistance to hot water edge penetration; uniform thickness, fine paper surface, good surface smoothness, and good printing adaptability. FK1 has good post-processing adaptability and can meet laminating, die-cutting, ultrasonic, thermal bonding and other processing techniques, and has good cup/bowl forming effects. After being coated with PE on one side, the cups (hot cups) are made to hold ready-to-eat drinking water, tea, beverages, milk, etc.; after being coated on both sides, the cups (cold cups) are made to hold cold drinks, ice cream, etc. BIO coating is also available to FK1, which is biodegradable and more environmentally friendly.

2. APP – Natural Hearty/FKO+PE: special paper for paper cups GSM: 170/190/200/210 (high bulk) Compared with FK1, FKO is of high bulk, it has the advantage of being more light-weighted, which save the costs.

3. APP – FNO/FCO FNO GSM: 210/240/340 (high bulk) FCO GSM: 230/245/260/275 (high bulk) If you have a need for bowl making, FNO/FCO is a great choice. FNO/FCO is the special paper for bowls. After coating with PE, it can be applied as fast food containers for rice, vegetables, soup and other foods.

BOHUI - Coated Food Grade Paper

1. BOHUI – Allyking Cream/GCU+PE: Surface two layers blade coated GSM: 215/220/235/240/250/270/295 GCU has super high bulk(1.63 – 1.73), it is ultra-lightweight and has high stiffness, good uniformity, smooth and delicate surface, exquisite printing effect, and excellent box-forming performance; GCU is low-carbon and environmental friendly with lower paper cost. Due to it’s unique water-resistant formula, GCU can be used for frozen and chilled food (fresh, meat, ice cream, frozen food, etc.) and cold chain storage and transportation. In addition, it can also be used for solid food (popcorn, cake, etc.) packaging. GCU Materials is approved by food certification, non-fluorescent; Passed FSC certification and complies with ROHS/REACH/FDA and other directives and regulations;

2. BOHUI – PCC+PE: Surface Two Layers Blade Coated GSM: 180/190/210/240/260/280/300/320/330/350 Fine coating, low PPS, high paper smoothness. Uniform thickness, good surface flatness, excellent offset flexo printing suitability, uniform printing ink, high stiffness, high printing speed. It has good post-processing adaptability, and the back side can meet processing techniques such as lamination(coating) and cup making; Comply with QS food certification, non-fluorescent, FSC\PEFC certification, the product is sent to the annual inspection with GB4806 food-grade white card series of standards, ROHS\REACH\FDA21 Ⅲ and other European and American packaging directives, regulations and other compliance reports. PCC can be laminated with single side or double side PE coating. With single side PE coating PCC can be used to make hot beverage cups to hold ready-to-eat drinking water, tea, drinks, milk, etc. With double side PE coating can be used to make cold beverage cups to hold cold drinks, ice cream, etc.

3. BOHUI – CKB+PE: GSM: 200/230/250/270/300/325/360 CKB (Coated Kraft Back) is made of 100% pure virgin fiber from responsibly managed forests. It is food-safe packaging board that stands up to cold and wet environments;

APP - Coated Food Grade Paper

1. APP – FVO+PE: GSM: 215/235/250/275/295/325/365 FVO is lightweight, of high stiffness and good uniformity. Materials approved by food certification, non-fluorescent; FVO is lightweight food packaging special paper, it is suitable for packaging boxes due to its smooth and delicate surface and exquisite printing effect. It is QS certified, passed FSC certification and complies with ROHS/REACH/FDA and other directives and regulations; FVO can be used to make facial tissue packaging, high-grade cosmetic packaging. Suitable for maternal and infant skin-friendly products, feminine products, personal hygiene products. Also suitable for solid food packaging products, such as popcorn buckets, cereal, cake boxes, and solid food Packaging: like milk powder, and so on. FVO can replace social card/white board paper and so on. It can also reduce cost.

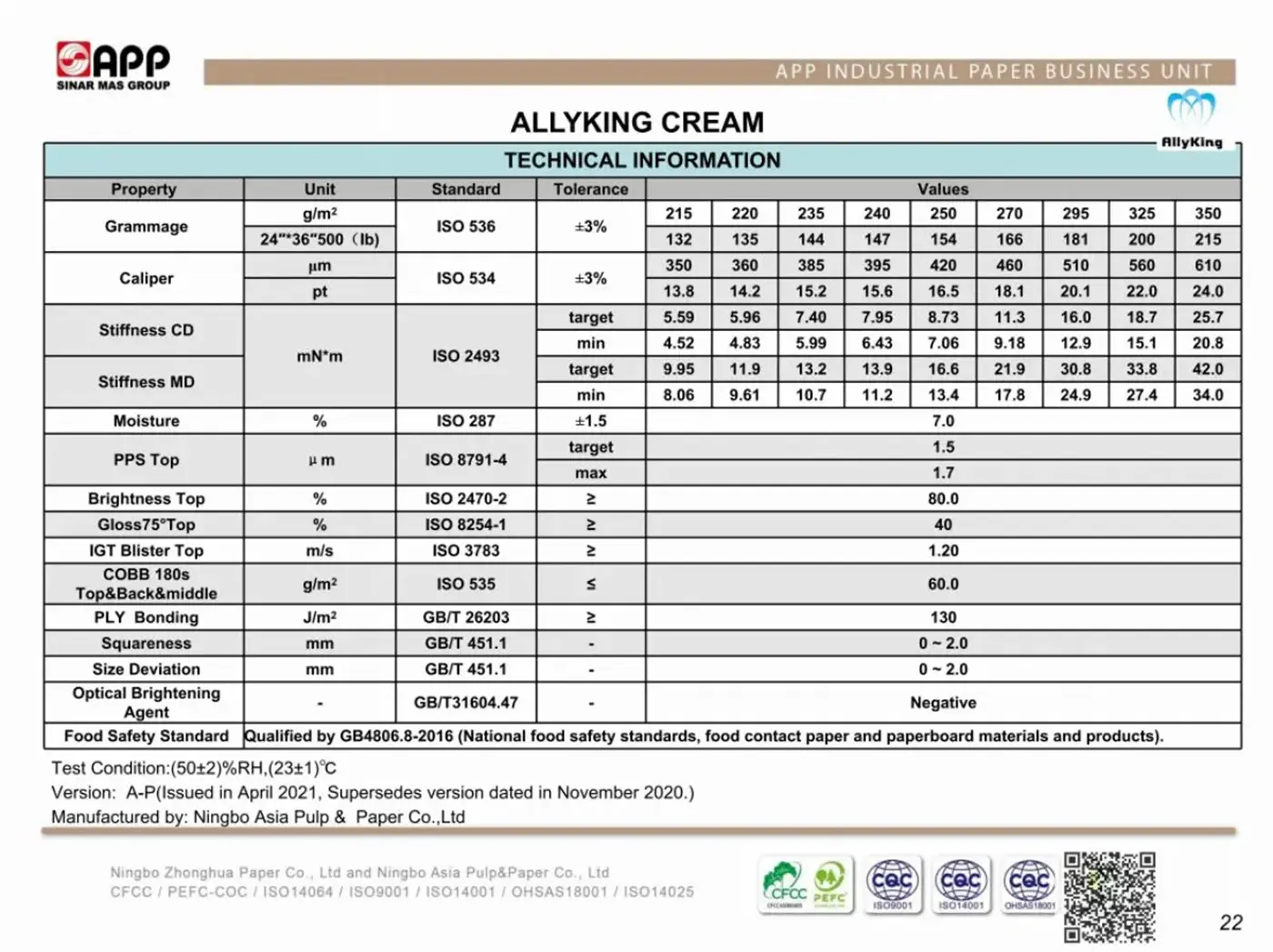

2. APP -Allyking Cream/ GCU+PE: GSM: 215/220/235/240/250/270/295/325/350 APP GCU passed QS certification, and have passed the tests of many international standards such as the US and EU, and are in compliance with the food contact regulations and standards. APP GCU is super high bulk product so it is ultra-lightweight, made entirely from wood pulp, without fluorescent whitening agents, has good stiffness and uniform thickness. After post-processing, GCU is well formed and does not deform, and can be laminated on the back (please confirm the printing effect on the front before laminating). Unique water-resistant formula, suitable for solid food packaging, frozen and refrigerated product packaging. It is widely used in various types of packaging that are in direct contact with food and social packaging such as medicine boxes and daily necessities. It is ultra-lightweight and has the advantages of good printing, processing and molding performance. As a ultra-lightweight food-grade ivory board, it provides the industry with environmentally friendly, safe and lightweight paper options and solutions. It can bring the ultra-light experience of packaging, use less raw materials to realize the same packaging texture needs, reduce the burden for life, and reduce the cost of paper. Compared with other papers, it has good stiffness, giving the package a more excellent texture experience, flat and delicate surface with excellent paper strength, guaranteeing the product performance and printing effect of the package. Stiffer and stronger, making the package more high-grade. Passed PEFC green forest certification from forest to paper. Strict supplier access mechanism and rigorous quality control mechanism for raw materials to ensure the traceability and quality of raw materials. And have passed the QS certification. More Functional. Unique water-resistant formulas are incorporated to make paper packages easy to handle for cold chain storage and transportation, so that fresher food can be delivered to you conveniently and completely.

You may find APP/BOHUI both have the Allyking Cream/GCU, yes, it is true. Since BOHUI paper mill was acquired by APP Group, their machinery, equipment and teams have been slowly integrated, and the quality of paper produced by Bohui Paper has gradually improved to be comparable to that of APP. This is undoubtedly a good thing for consumers.

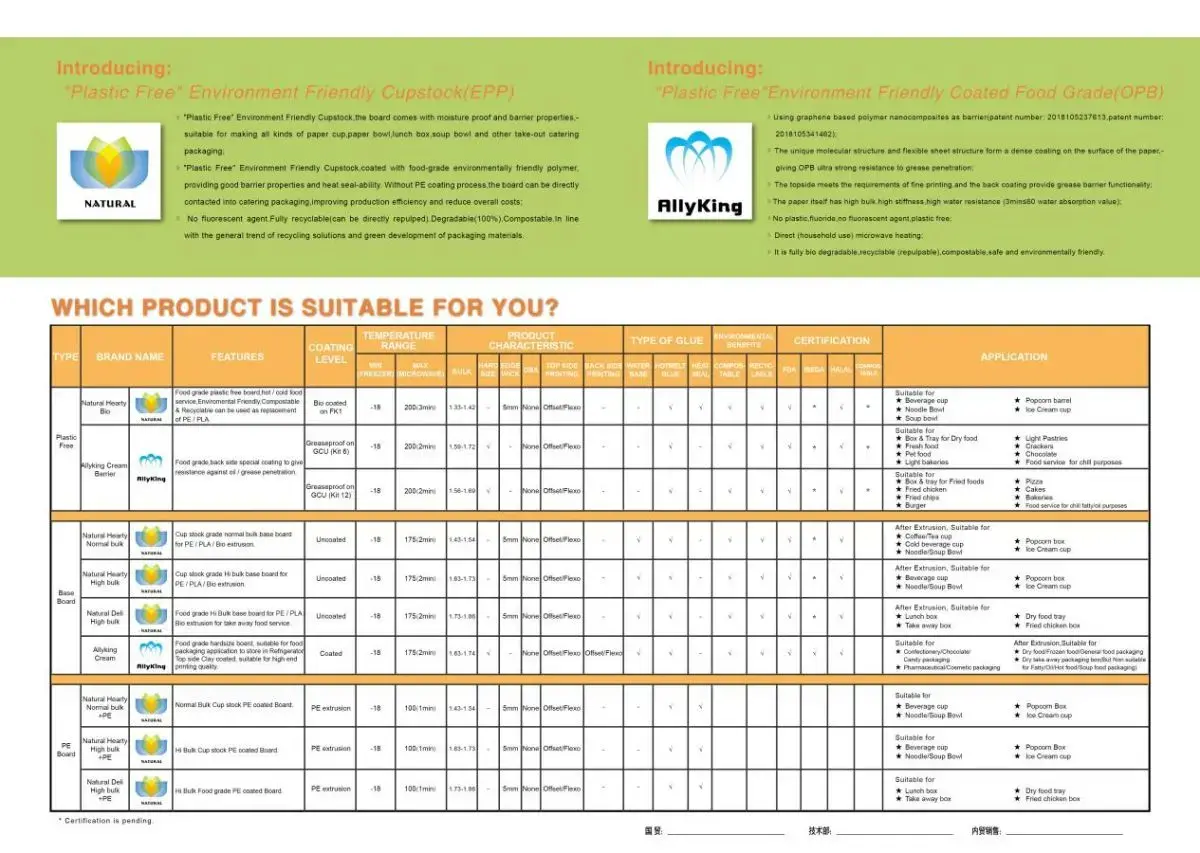

Plastic-Free Paper

Our “Zero Plastic” Main Products Are as Follows

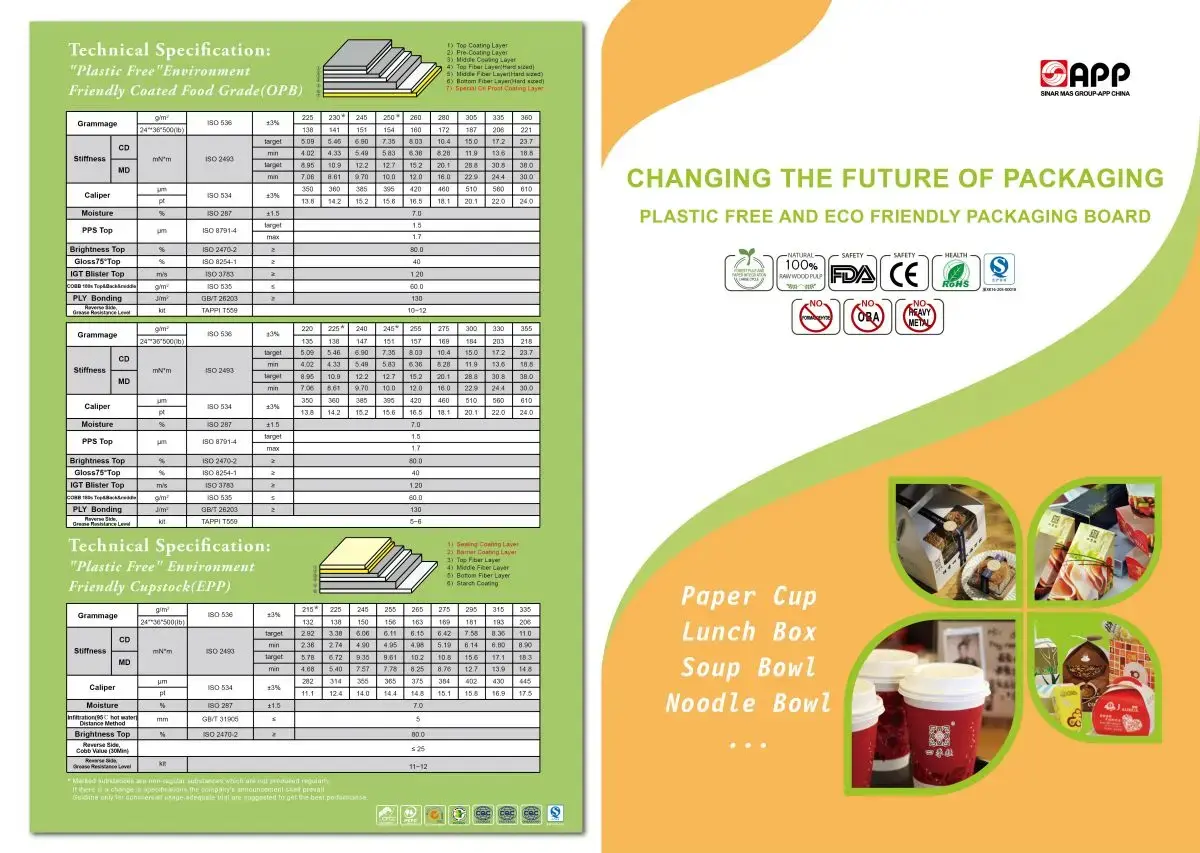

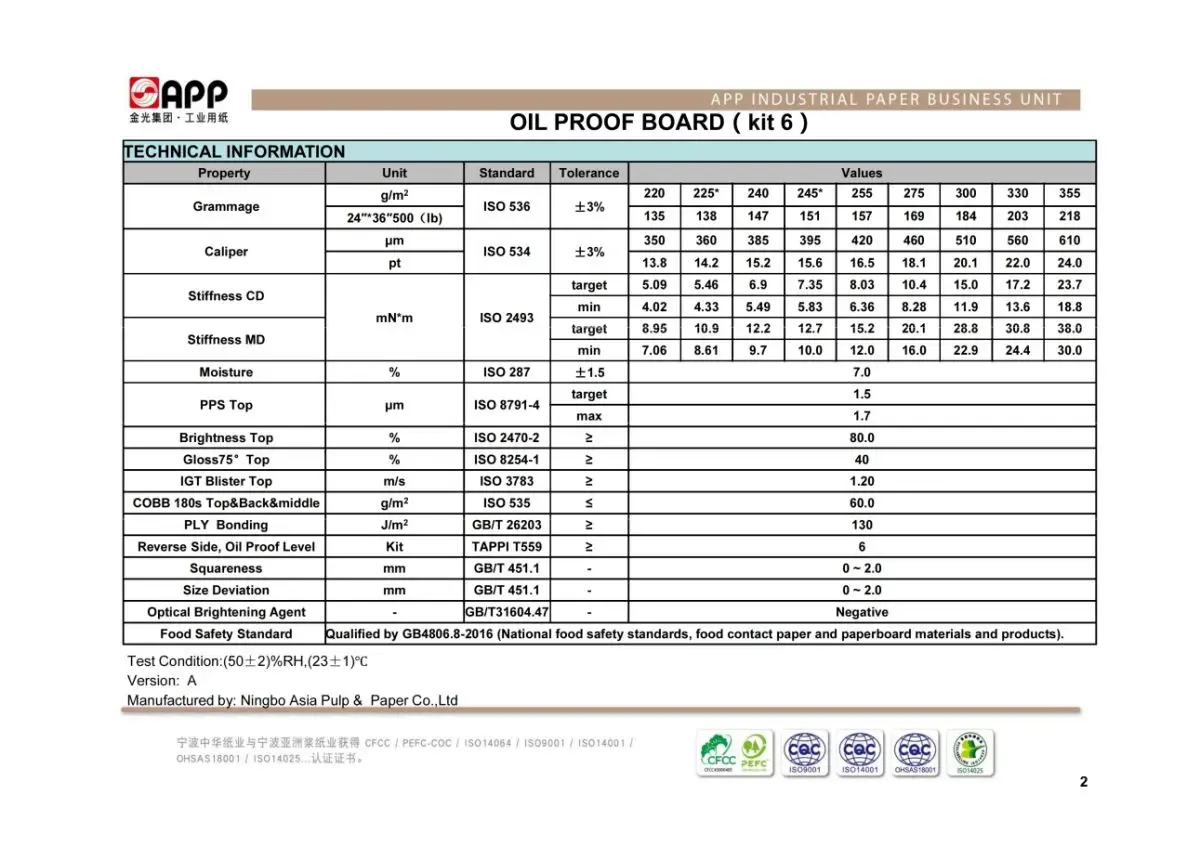

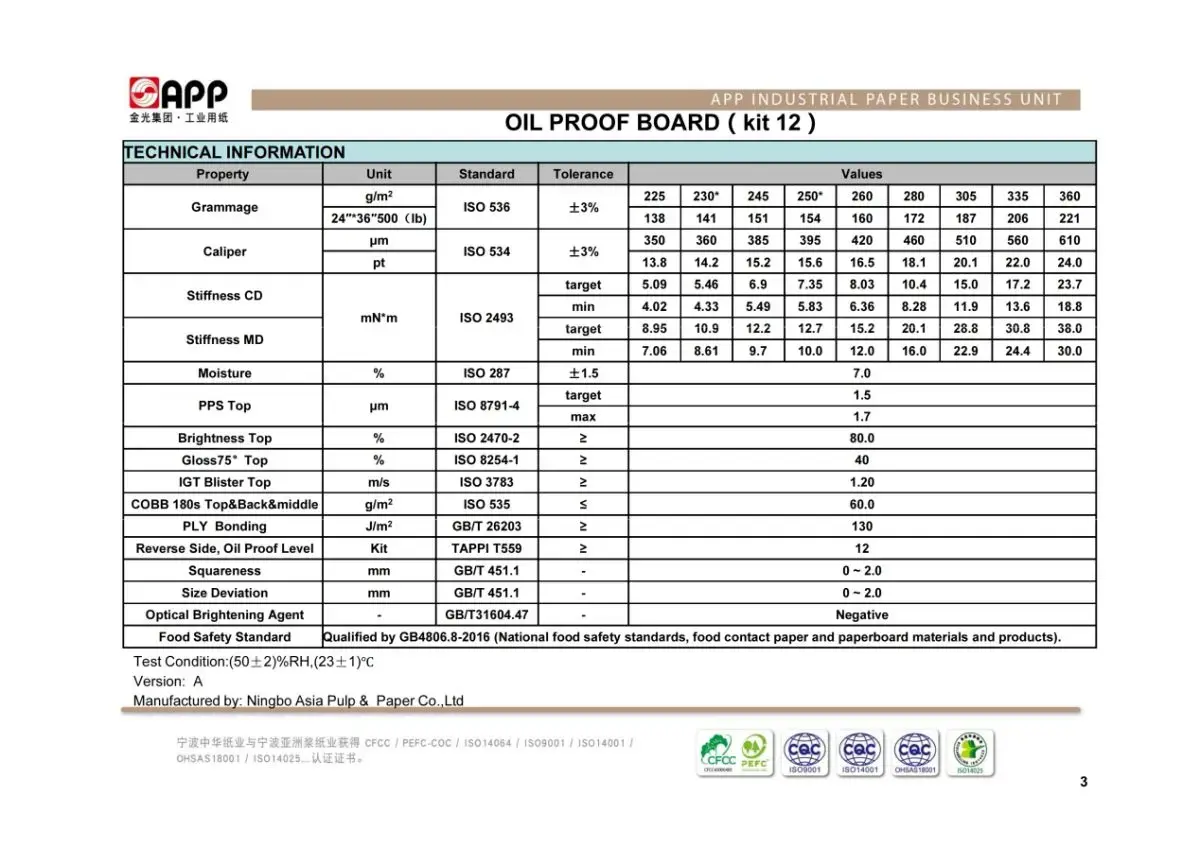

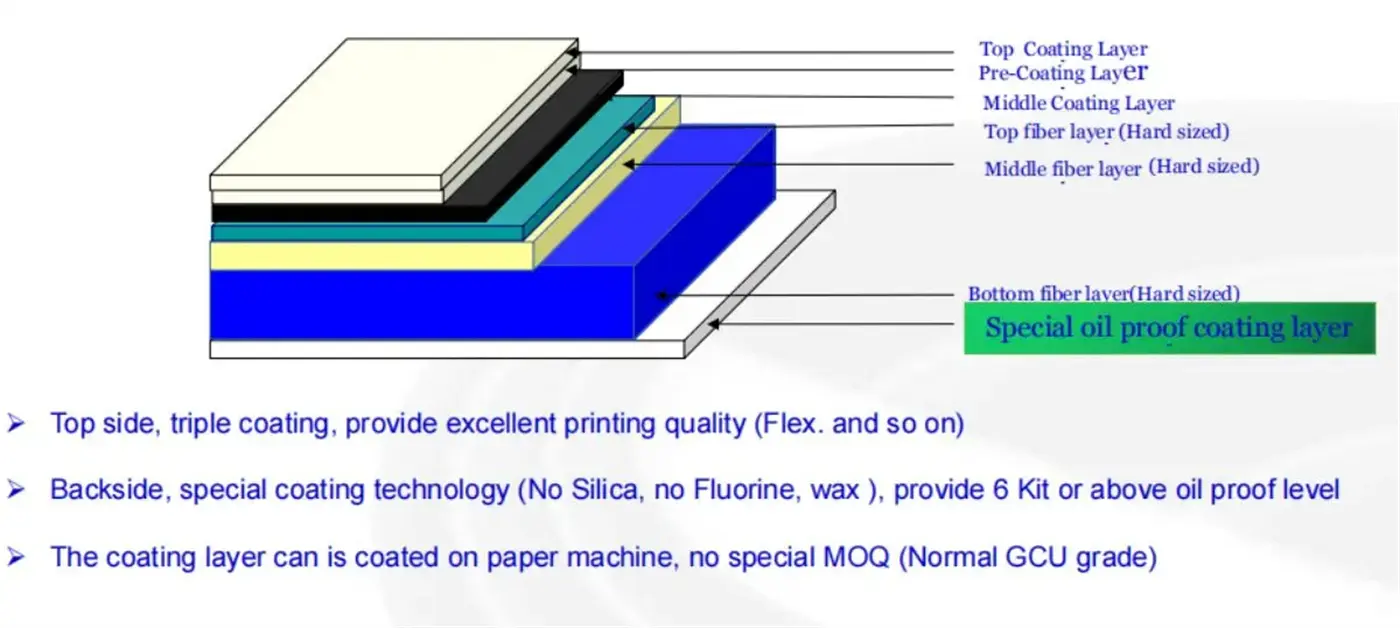

1. APP - OPB:

(Paper Base is APP–Allyking Cream GCU)

GSM: GCU paper base+5g Kit 6

GSM: GCU paper base+10g Kit 12

The technology focuses on a unique coating technology which provides the coated board with enough oil resistance and zero odor. OPB also focuses on three key demands in the market: repulpable (being recycled in paper or board stream), biodegradable, and compostable. Fluoride products like PFOS and PFOA are harmful to health despite their excellent oil resistance performance, so we have to find better solutions to reduce their overuse in the world. And now more and more governments require stopping the use of paper products with fluoride, especially for food contact paper. Fluoride-free oil repellent agent is used instead of traditional products.

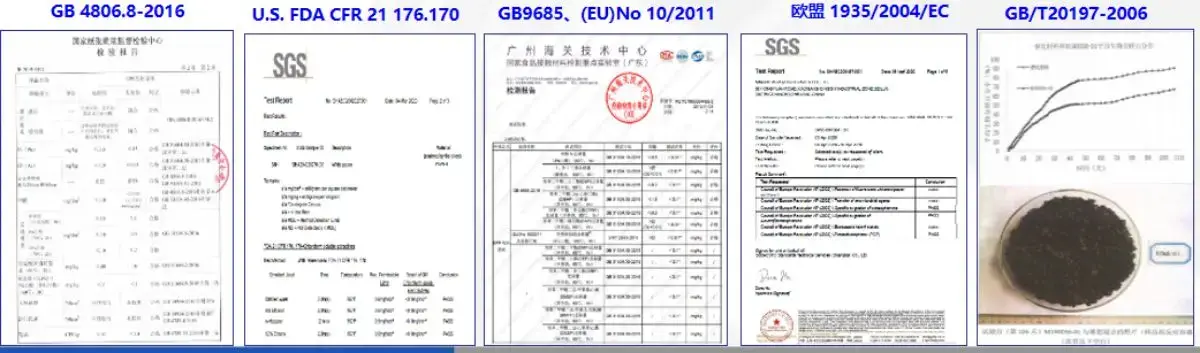

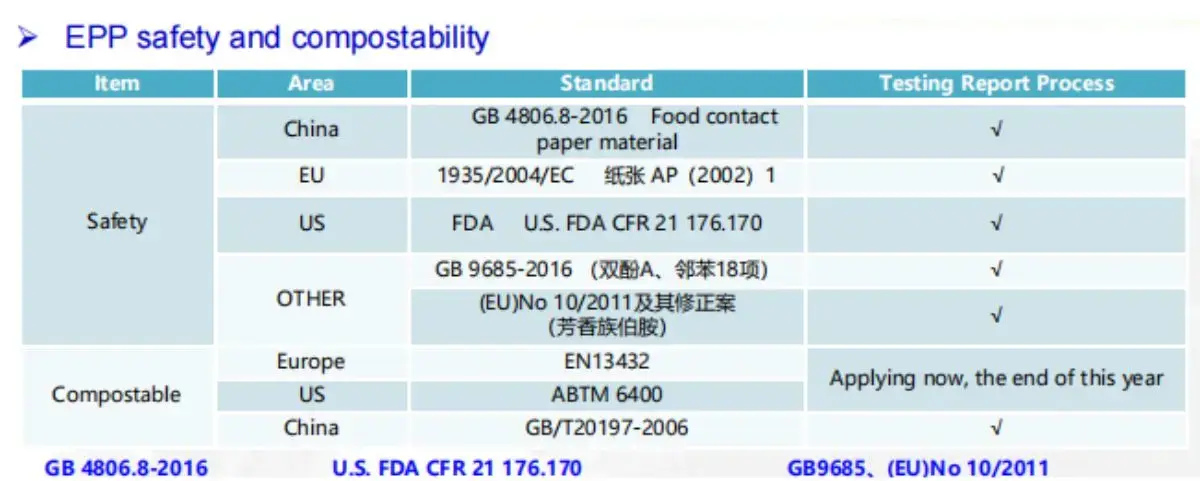

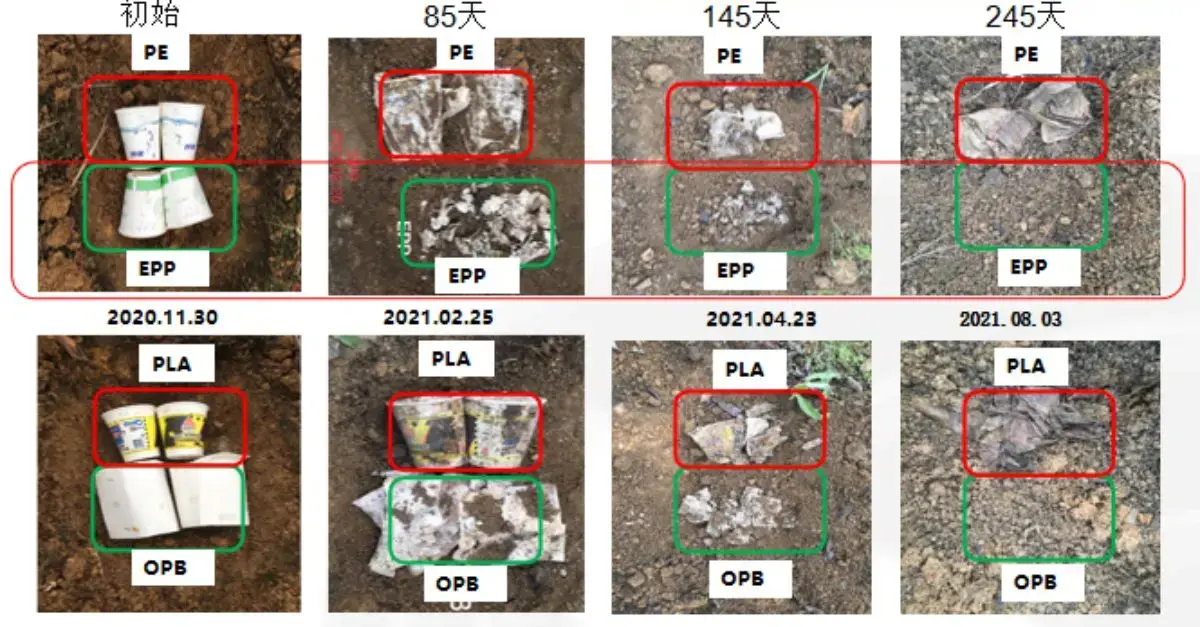

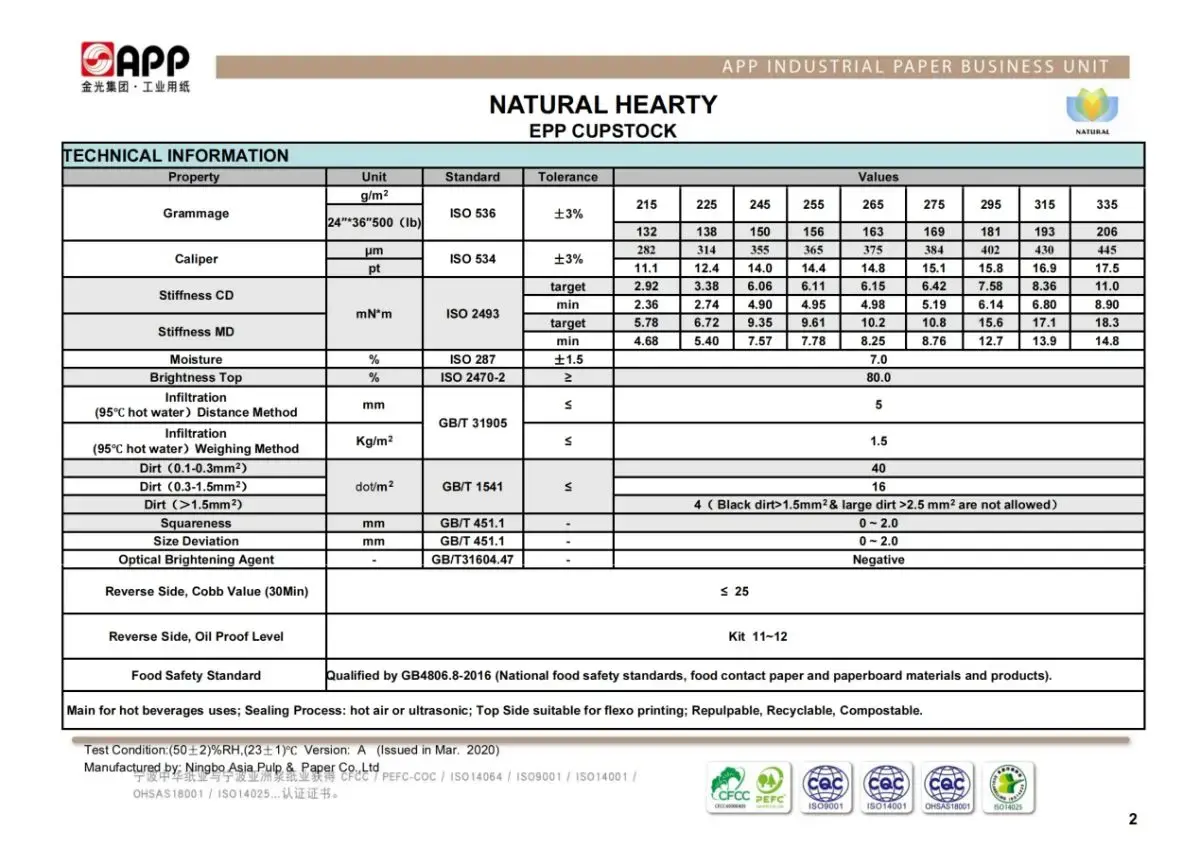

2. APP - EPP

GSM: 200/220/240/270/290/310/330

In recent years, the international community has increased its efforts to control, from “Plastic Restriction” to “Plastic Prohibition”, and introduced a series of policies or decrees. For the sake of sustainable development, APP China launched EPP which is a special process to create products. EPP is a water-based dispersion coating, which can be processed directly on the paper machine or on top of the coated fabric; it is degradable and recyclable, which is more environmentally friendly than PLA/BIO, which can only be degraded and not recycled.

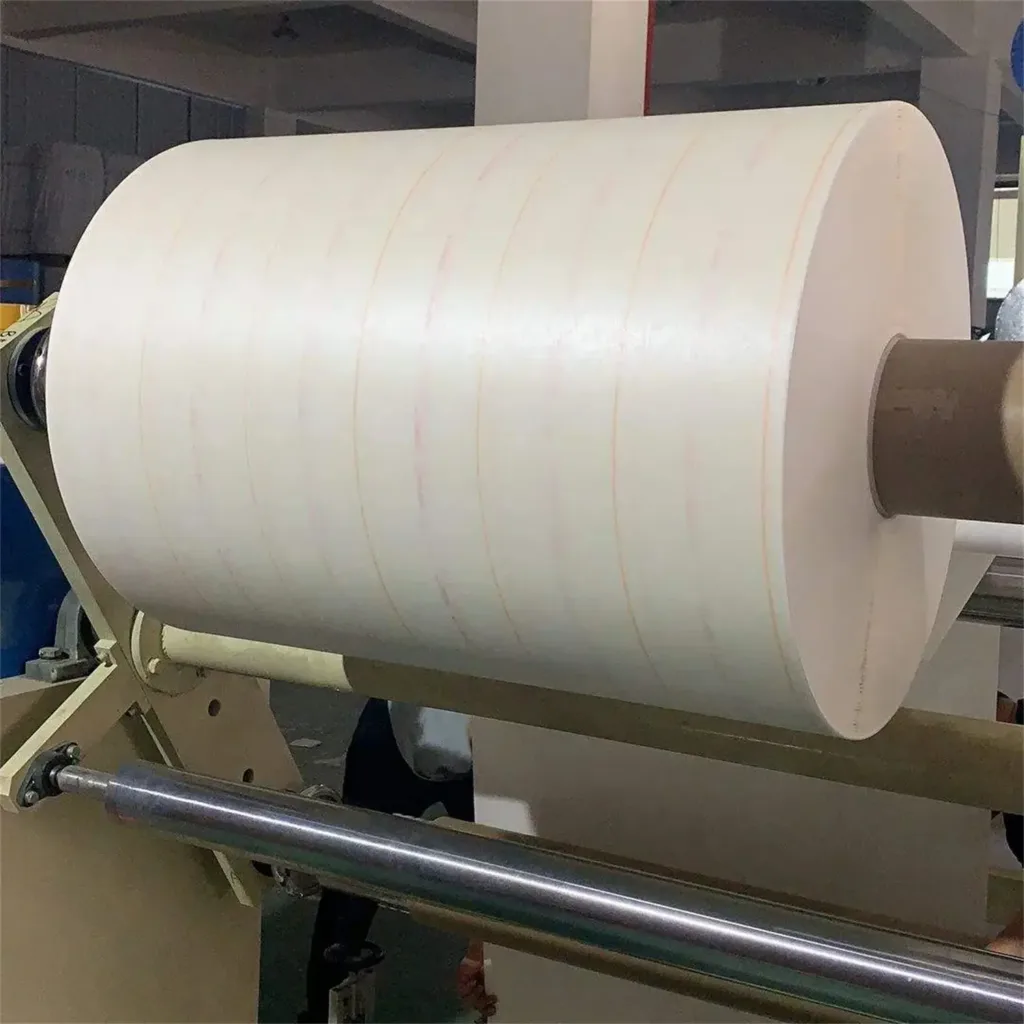

Our Paper Workshop And Sample Room

At present, Sure-Paper established long-term cooperative relations with more than 1,000 printing companies around the world. Besides deep and stable cooperation with APP/ BOHUI/ IP SUN these big paper mills, we also have our own processing factory and warehouse in local with 10 necessary machines such as cutting machine, slitting machine, make-up machine, thermal shrinkage packing machine, automatic packing machine. We’ve been in the paper industry for over 12 years.

Always trying our best to help our customers save cost, giving customers suggestions but we never take risk for paper quality. Our mission is to achieve a win-win situation with all of our customers!