In recent years, thermal paperhas become widely used across various industries. But have you ever wondered how the color appears on Thermal Paper when it is printed? Let’s dive into the basic principles behind the color development of thermal printing paper.

Coloring Principle of Thermal Paper

Thermal paper coloring can be divided into several basic principles, primarily based on different chemical mechanisms. The main coloring process can be summarized into the following methods:

-

Transparent Thermal Paper:The principle behind transparent thermal paper involves applying a layer of opaque wax coating on top of a gray or black Base Paper. When the thermal pen or print head heats the paper, the opaque wax melts and becomes transparent, allowing the color of the base paper to show through, creating the image.

-

Metallic Compound-Based Thermal Paper: This type of paper uses metal salt and oxidizing agent compounds. When heated, the metal salts melt and interact with the oxidizing agents, reducing the metal and causing it to release color. This process leads to the appearance of different hues in the paper.

-

Colorless Dye-Based Thermal Paper: In this case, a colorless dye with an internal ester ring is mixed with a color developer. When the paper is heated, the dye and developer interact, resulting in a color change, forming the text or image on the paper.

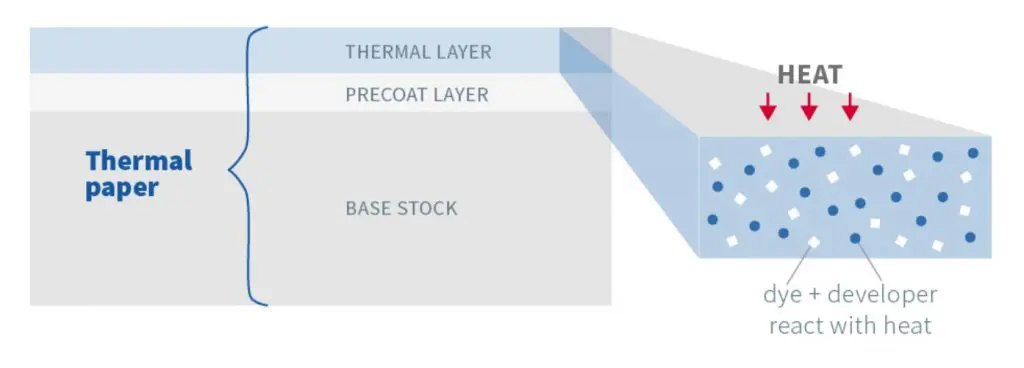

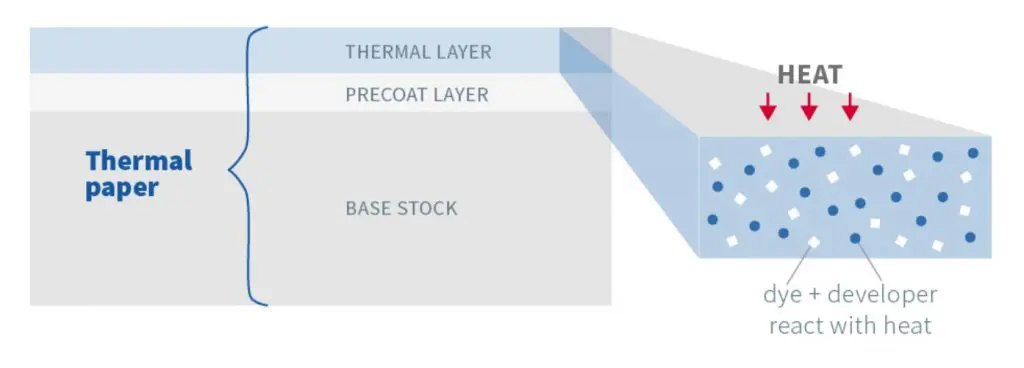

Thermal Paper Color Development Mechanism

When thermal paper is exposed to temperatures above 70°C, the thermal coating begins to change color. This color change occurs due to the unique composition of the thermal layer, which consists of two main components:

- Colorless Dye (or invisible dye): This component is usually based on chemical compounds such as crystal violet lactone (CVL), fluoran compounds, and non-colored benzylidene blue (BLMB).

- Color Developer: This is a chemical agent that reacts with the colorless dye to produce a visible color. Common color developers include compounds like phenolic acid, salicylic acid, and aromatic sulfone.

When exposed to heat, the colorless dye reacts with the color developer, resulting in the development of the image or text on the paper. The color produced can vary depending on the chemical composition of the dye, with common colors being blue, dark purple, or black.

Key Chemicals in Thermal Paper

Common colorless dyes (or invisible dyes) used in thermal papers include:

- Crystal Violet Lactone (CVL) (used in a triphenylmethane system)

- Fluoran-based compounds

- Benzylidene blue (BLMB) in non-colored systems

Common dispersing agents and additives include:

- Polyvinyl alcohol (PVA) (e.g., L-3266, GL-05, KL-03)

- Coating agents such as Gohsefimer Z-200, PVA T-350, and PVA N-300

Common color developers include:

- Phenolic compounds like PHBB (para-hydroxybenzoic acid), salicylic acid, and aromatic sulfone derivatives.

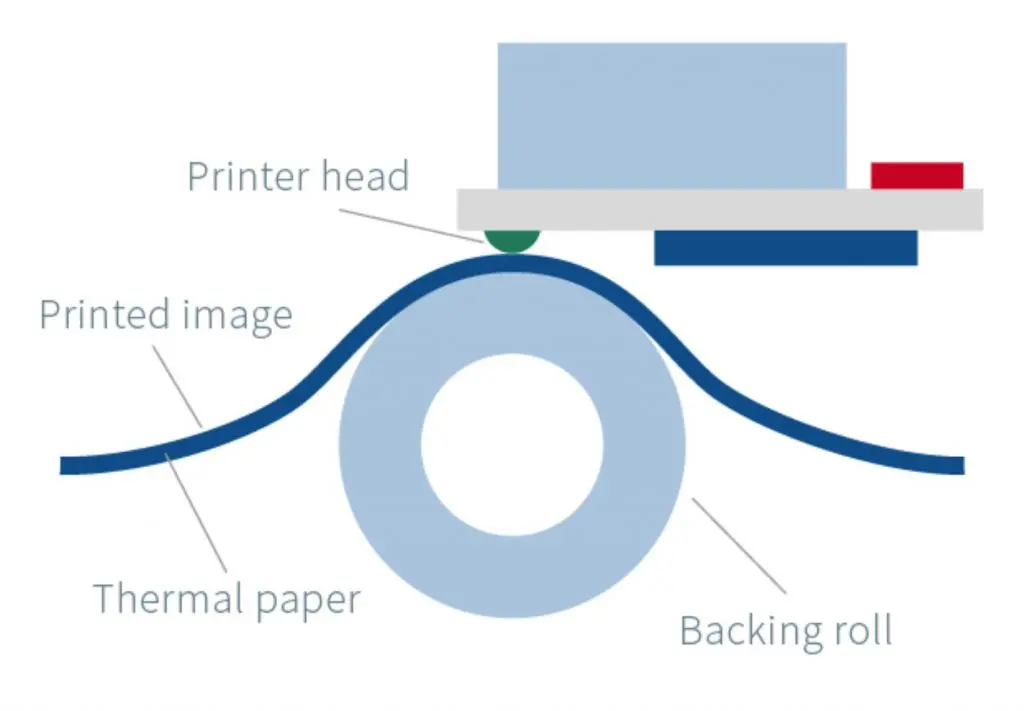

Practical Application in Printing

When the thermal paper is heated in thermal printers, the colorless dye and color developer interact to produce visible images or text. This is why thermal printers can print on such paper quickly and efficiently. Depending on the type of colorless dye used, the printed output can vary in color, ranging from blue to dark purple to black.

As the use of thermal paper continues to grow in various industries, from retail to logistics, understanding the science behind its operation can not only help in improving printing quality but also in exploring new applications of this versatile material.