Air humidity plays a crucial role in the quality and forming process of PE laminated paper. Laminated paper, typically Coated with plastic (such as PE, or PLA), is widely used in packaging applications due to its water, oil, and moisture resistance. However, as paper is a hygroscopic material, it is highly sensitive to fluctuations in ambient humidity, which can significantly affect its physical properties. Controlling humidity effectively is essential to ensuring the product’s quality during forming and processing.

The Impact of Air Humidity on Laminated Paper

(1) Paper’s Hygroscopic Nature

Before lamination, the Base Paper tends to absorb moisture from the surrounding air. When humidity levels are high, the paper absorbs excess moisture, leading to increased water content. This can result inwrinkling, deformation, and issues with the plastic coating’s adhesion during the lamination process. On the other hand, if the air is too dry, the paper becomes brittle, reducing its flexibility and processing capability, which can lead to cracking or tearing.

(2) Adhesion Performance of the Laminated Layer

In addition to affecting the paper’s structure, improper humidity can impact the adhesion between the paper and the plastic layer. In high-humidity conditions, the surface of the paper may become too moist, preventing the plastic from adhering evenly. This may lead to bubbles, *peeling, or **uneven lamination*, compromising the waterproof and protective qualities of the laminated paper. For industries such as food packaging, these defects are especially problematic as they can lead to product contamination or compromised quality.

(3) Dimensional Stability of the Paper

Changes in humidity levels can cause dimensional fluctuations in laminated paper. As the paper absorbs or loses moisture, it expands or contracts, potentially causing inaccuracies in product forming. This issue is especially critical when high precision is required, as the final product may not fit the specified dimensions, leading to improper sealing or structural inconsistencies.

The Impact of Air Humidity on Product Forming

(1) Precision and Structural Stability of Formed Products

During the forming process, such as making paper cups, food boxes, or other packaging items, fluctuations in air humidity can result in defects. In a high-humidity environment, the moisture absorbed by the paper makes it more pliable, which can lead to shape instability during paper cup forming. Products like paper cups may not hold their form, affecting the structural integrity and functionality of the product. When humidity is too low, the paper may become too rigid, causing cracking or splitting during the shaping process, which not only disrupts production efficiency but also results in higher waste rates.

(2) Surface Quality of the Finished Products

Humidity variations can also cause surface defects in laminated paper products. Excess moisture may cause the paper to wrinkle or fold improperly, leading to visible imperfections such as creases, *indentations, or even **cracks* in the product’s surface. In industries such as premium food or pharmaceutical packaging, where surface smoothness and aesthetic quality are crucial, this issue can severely impact the product’s marketability.

Methods for Controlling Humidity Issues

To mitigate the effects of air humidity on laminated paper and ensure the quality of the final product, several control methods can be implemented:

(1) Maintain a Stable Production Environment Humidity

The production facility’s air humidity should be kept within a constant range, typically between 40% and 60%, depending on the specific product requirements. In high-humidity conditions, *dehumidifiers* can be installed to lower moisture levels, whereas humidifiers can be employed to increase humidity when the air is too dry. Maintaining a stable humidity level ensures the paper’s consistency during processing.

(2) Pre-Treat the Paper

Pre-treatment processes, such as adjusting the paper’s moisture content before lamination, can help ensure the paper remains within acceptable moisture levels. Using specialized equipment, manufacturers can measure and correct the paper’s water content to meet the requirements of the lamination process, reducing the risk of defects.

(3) Real-Time Monitoring

The use of humidity sensors and intelligent control systems in modern production facilities allows for real-time monitoring of ambient air humidity. These systems can automatically adjust environmental conditions, ensuring a stable atmosphere throughout the manufacturing process. This not only improves production efficiency but also ensures consistent product quality.

(4) Material Selection and Process Innovation

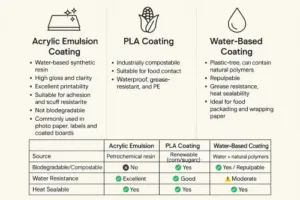

With advances in material science, newer laminating materials such as PLA coatings are more sensitive to humidity. As these environmentally friendly materials become more widely used, humidity control will become even more critical. Manufacturers can also adopt advanced lamination techniques, such as dual-sided lamination or multi-layer composite coatings, which better protect the paper from moisture absorption during and after production.

Conclusion

Air humidity has a significant impact on both the quality of laminated paper and the final formed product. Variations in ambient moisture can affect the paper’s physical properties, such as dimensional stability, adhesion, and flexibility, which, in turn, affect the product’s overall performance and appearance. Effective humidity control methods, such as maintaining stable production environments, pre-treating paper, and utilizing real-time monitoring systems, are essential to minimizing these effects and ensuring the production of high-quality laminated paper products. As packaging materials evolve to include more sustainable options, managing environmental factors like humidity will become increasingly important for manufacturers.