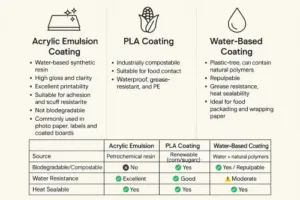

Water-based coatings(EPP) have emerged as a sustainable alternative to traditional plastic coatings in the quest for eco-friendly packaging solutions. Compared to PE and PLA coatings, they require less material to prevent leakage, making them more sustainable. Composed of natural materials like starch and cellulose, minerals such as calcium carbonate, and synthetic polymers like acrylic acid and PLA, waterborne coatings offer environmentally friendly properties that appeal to both manufacturers and consumers. By reducing reliance on petroleum-based plastics, these coatings pave the way for a more sustainable future in food packaging.

What are Water-Based Coatings:

Water-based coating is made by mixing the following substances:

- Water

- Natural materials, such as starch and cellulose

- Minerals, such as calcium carbonate

- Synthetic polymers such as acrylic and PLA

Water-based coatings offer an eco-friendly alternative to traditional plastic coatings, making compostable paper cups more compostable. Methods like reverse roll coating ensure effective application, dealing with different viscosities and ensuring even distribution while maintaining necessary barrier properties and environmental benefits.

Why Water-Based Coatings Are Becoming More Popular:

Water-based coatings are gaining popularity due to several key factors:

-

Shifting Consumer Preferences: Growing demand for sustainable products is driving the popularity of environmentally friendly coatings.

-

Environmental Awareness: The focus on environmental protection has increased the need for sustainable packaging solutions, leading to the adoption of water-based coatings.

-

Design Innovations: The development of reusable paper cups and eco-friendly packaging aligns with environmental standards, further promoting water-based coatings.

-

Sustainability Advantage: Water-based coatings offer a significant sustainability advantage with their plastic-free composition and 100% biodegradability, appealing to environmentally conscious consumers and regulators.

As environmental concerns take precedence, the industry is witnessing a notable shift towards water-based coatings, driven by consumer preferences, environmental awareness, and sustainable design innovations.

Challenges of Water-Based Coated Paper Cups:

-

Cost Barrier: Higher production costs make water-based Coated paper cups more expensive than PE-lined cups, limiting their widespread adoption.

-

Limited Availability: Water-based coated paper cups are not as widely accessible in the market as PE-lined cups, posing a challenge due to restricted availability.

-

Performance Variance: Water-based coatings may lead to a shorter shelf life compared to PE coatings, impacting product durability and storage capabilities.

-

Regulatory Compliance: Proper labeling is required for aqueous-lined cups under the Single-Use Plastic Directive due to their polymer content, adding a regulatory compliance burden.

-

Consumer Education: Educating consumers about the advantages and limitations of water-based coatings is essential for fostering broader acceptance and understanding in the market.

Despite these challenges, embracing water-based coatings represents a significant stride towards sustainability in the paper cup industry, addressing the environmental impact of plastic coatings and meeting the rising demand for compostable and eco-friendly packaging. As the industry continues to innovate, water-based coatings are driving the shift towards sustainable paper cup production.