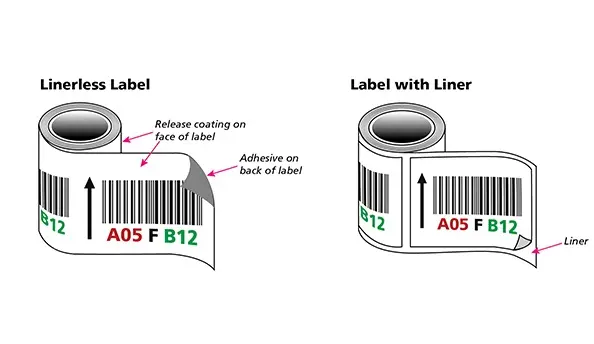

When using traditional self-adhesive labels, the surface material is directly peeled off from the backing Paper by hand tearing or an automatic labeling machine. After that, the backing paper will be useless without value.

A Linerless label is a self-adhesive label without a liner.

When printing, the graphics and text are first printed on a traditional self-adhesive label machine, after that a layer of silicone oil is applied to the surface of the printed self-adhesive label; Then apply a layer of hot melt adhesive prevents the self-adhesive labels from sticking to each other; then a tear line is set on the label to facilitate tearing, and finally it is rolled up.

The silicone oil on the surface of the sticker is waterproof and anti-fouling, and protects the graphic information on the surface of the sticker, greatly improving the printing effect!

In supermarket scenarios, Linerless labels can be applied to the packaging of various products such as cooked food, raw meat and seafood, and baked goods.

The advantages of Linerless Label:

1. No backing Paper Cost

Without the backing paper, the cost of glassine backing paper is zero, achieving energy saving and emission reduction.

2. Reduce label surface material costs

The surface material of the Linerless label does not have any loss, and it is easy to tear off through the preset tear line between the label and the label. Can save 30% of raw material costs.

3. Reduce transportation and warehousing costs

With the same roll size, Linerless label can accommodate more labels, which can roughly double the number. The roll material of the same format and thickness can accommodate more than 50% more labels than traditional self-adhesive roll materials, which reduces the space for warehousing, reduces storage costs and Logistics costs too.

4. Reduce the wear of the print head.

In order to prevent adhesion on the surface of the linerless label, a layer of silicone oil is applied to the surface of the face material. This layer of silicone oil reduces the friction between the print head and the face material, reduces the wear of the print head, and saves printing costs.

The disadvantage of Linerless Label:

Since the interconnection of Linerless labels relies on zigzag tear lines, the more mature shapes are currently limited to rectangles. Self-adhesive labels on the market often come in a variety of shapes, and just rectangles cannot meet market requirements.

In all, Linerless Label reduces the felling of mature trees, reduces the consumption of fresh water and other energy, and reduces carbon emissions. Coupled with the reduction of other costs, it is in line with the concept of green printing.